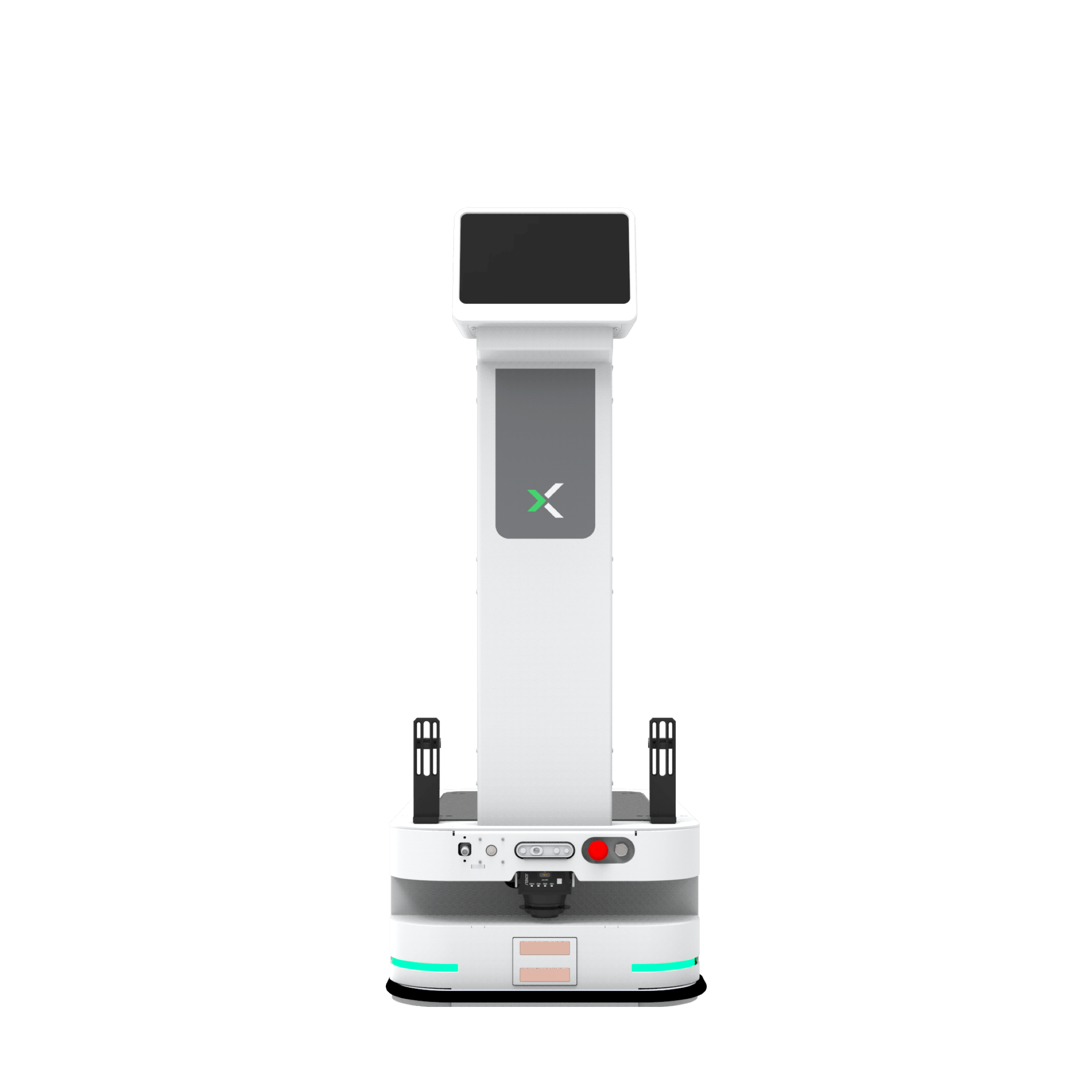

Vision-Based Autonomy for Industrial Complexity

Omni Fleet: Your Complete Material Handling Suite

Omni Fleet

Your Complete Material Handling Suite

Honors & Recognition

Industry Awards

Our Mission

To make robots a part of everyday work and life, empowering people to focus on creativity, exploration, joy, and meaningful challenges — by delivering intelligent automation to industries around the world.

Our Vision

To become the global leader in AMR technology, redefining the future of intelligent logistics and manufacturing.

Proven Performance

5-9

Month ROI

2-3X

UPH Increase

50%

Operational Cost Savings

4

Weeks Rapid Deployment

4500+

AMR Deployed

250+

Facilities

Industry Application

Learn from 1 of over 250 deployments

3PL, Retail, ECommerce, Health & Personal Care, Food & Beverage, Home Furnishing, Electronics

OEM (Stamping, Welding, Coating, Battery, Final Assembly),Tier 1 & 2 Suppliers (Electronics, Components, Tires, etc.)

Hospital, Library

HEAR FROM OUR CLIENTS

Our picking efficiency has improve significantly. Individual pickers have doubled their units picked per hour. Also, our error rate has dramatically been reduced. Before, our error rate was roughly 1 in 10,000. After applying ForwardX’s AMRs with RFID technology, we have brought that rate down to about 1 in 100,000.

User Evaluation

World’s 1st

Let’s start the conversation and see how ForwardX Robotics can help you improve your operations.