Case Studies

Automotive: DongFeng Welding Workshop with Flex and Max AMRs

To avoid high-intensity, error-prone, and dangerous labor practices in this automotive welding shop, Dongfeng sought a solution requiring ForwardX’s Flex and Max series AMRs. Workers

Chery Ordos

In Ordos, China, Chery Automotive has partnered with ForwardX Robotics to revolutionize their manufacturing processes at the new Chery Ordos Factory. This state-of-the-art facility features

E-commerce:Gaatu with Max 600-L

https://www.youtube.com/watch?v=u7cgpR1QrvA Gaatu’s Solution: With 10 Max 600-L AMRs, ShipSage automated its case picking operations across inbound, picking, and outbound zones at its Tracy, California warehouse.

Retail: Highline Warren with Flex 300-SCB

https://youtu.be/lHHE8-b09-c Highline Warren’s Solution With 20 Flex 300-SCB AMRs, Highline Warren streamlined its order fulfillment process. AMRs begin at the induct station, where operators scan

A Leading Roof System Manufacturer

Global Leading Roof System Manufacturer Solution At this roof system manufacturing facility, five of ForwardX’s MAX-1500L AMRs handle material transport across multiple production line stations.

E-commerce:Gaatu with Max 600-L

https://www.youtube.com/watch?v=u7cgpR1QrvA Gaatu’s Solution: With 10 Max 600-L AMRs, ShipSage automated its case picking operations across inbound, picking, and outbound zones at its Tracy, California warehouse.

ShipSage by Gaatu

Max 600-L AMRs are assigned to pick empty pallets and take them to the designated picking points. Here, the AMRs collaborate with human workers who

LI & FUNG ECommerce Warehouse

In this intralogistics scenario, eight Flex 300 AMRs outfitted with a conveyor top module receive tasks from the company’s WCS and integrate with conveyors in

JD Beverage Warehouse

Facing rising recruitment and training costs, fluctuating seasonal demand, high error rate, and high consumer expectations, JD.com turned to ForwardX. Together, they formed a solution

SF DHL Coffee Distribution

DHL partner, SF Supply Chain China, is the leading supply chain service provider in China. It currently has warehousing and logistics facilities in more than

ITOCHU Logistics Corporation

With complex workflows, a high error rate, fluctuating seasonal demand, and the high cost of recruitment and training, ITOCHU worked with ForwardX to come up

L’Oréal Automatic Scale

In this intralogistics scenario, eight Flex 300 AMRs outfitted with a conveyor top module receive tasks from the company’s WCS and integrate with conveyors in

LI & FUNG ECommerce Warehouse

In this intralogistics scenario, eight Flex 300 AMRs outfitted with a conveyor top module receive tasks from the company’s WCS and integrate with conveyors in

JD Beverage Warehouse

Facing rising recruitment and training costs, fluctuating seasonal demand, high error rate, and high consumer expectations, JD.com turned to ForwardX. Together, they formed a solution

JD Home Appliance Warehouse

Eleven of ForwardX’s Max AMRs were used to tackle physically demanding tasks and increase the accuracy and efficiency of picking processes. After integrating with JD.com’s

JD Cosmetics Warehouse

The cosmetics warehouse suffered from high labor and recruitment costs, complex workflows, and high order volume. JD.com and ForwardX devised a solution using ForwardX’s overhead

JD Small Appliance Warehouse

The small appliance warehouse’s WMS generates and distributes the task order to the AMRs. Workers and AMRs meet at designated picking points, which the AMRs

Kelun Pharmaceutical

Three Apex 1400-L autonomous forklifts were implemented to streamline the outbound process. Running at all hours with the help of opportunistic charging, the autonomous forklifts

Top 3PL Cosmetics Warehouse

With complex workflows due to providing mainly B2C logistics services, and roughly 4,000 SKUs from 5 merchants, the warehouse ships about 2,400 daily orders. Picking

L’Oréal Autonomous Forklift

Working with Max series AMRs, the Apex 1400-L autonomous forklift completes inbound logistics and assists in picking processes. It also operates with pinpoint precision and

Pharmaceutical B2B Distribution

This is a logistics picking and sorting scenario, where SKUs of different types and quantities are picked, sorted onto the appropriate rack level, and taken

L’Oréal Cosmetics Warehouse

ForwardX successfully deployed over 10 Max AMRs in the group’s Suzhou warehouse to realize an intelligent person-to-goods picking solution. The picking area is about 53,800

Well-Known Food Manufacturer

A global leader in the food industry collaborated with ForwardX Robotics to optimize intralogistics material handling, ensuring the delivery of trusted food products worldwide. To

JD Beverage Warehouse

Facing rising recruitment and training costs, fluctuating seasonal demand, high error rate, and high consumer expectations, JD.com turned to ForwardX. Together, they formed a solution

SF DHL Coffee Distribution

DHL partner, SF Supply Chain China, is the leading supply chain service provider in China. It currently has warehousing and logistics facilities in more than

World Leading Supermarket

After receiving a task from the f(x) Fleet Manager, the Flex AMR automatically picks up a rack and drives to the pick-and-sort destination. A worker

JD Beverage Warehouse Cross Docking

To eliminate the need for storage and expedite the process of material transfer from the 3PL to other businesses, Apex series autonomous forklifts are utilized for

JD Rice & Flour Warehouse

Within the rice and flour warehouse, its MES system generates task orders that are grouped, assigned, and dispatched by ForwardX’s f(x) Fleet Manager. AMRs can

LI & FUNG ECommerce Warehouse

In this intralogistics scenario, eight Flex 300 AMRs outfitted with a conveyor top module receive tasks from the company’s WCS and integrate with conveyors in

Hiocloud Home Furnishing Warehouse

Hiocloud and ForwardX worked together on a ForwardX solution to simplify workflows, increase productivity, and reduce costs and errors. Seven Max AMRs communicate with handheld

TCL 5G Smart Factory

Max 600-L AMRs are assigned to pick empty pallets and take them to the designated picking points. Here, the AMRs collaborate with human workers who

Household Appliance Manufacturer

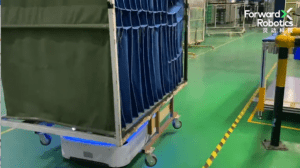

The line worker completes the material ordering through a PDA, and the warehouse staff begins to load the material after receiving a task. After the

Automotive: DongFeng Welding Workshop with Flex and Max AMRs

To avoid high-intensity, error-prone, and dangerous labor practices in this automotive welding shop, Dongfeng sought a solution requiring ForwardX’s Flex and Max series AMRs. Workers

Chery Ordos

In Ordos, China, Chery Automotive has partnered with ForwardX Robotics to revolutionize their manufacturing processes at the new Chery Ordos Factory. This state-of-the-art facility features

A Leading Roof System Manufacturer

Global Leading Roof System Manufacturer Solution At this roof system manufacturing facility, five of ForwardX’s MAX-1500L AMRs handle material transport across multiple production line stations.

Global Leading Tire Manufacturer

At this tire manufacturing facility, nine of ForwardX’s customized Apex 2000 autonomous forklifts manage raw material delivery to eight production lines. The Apex have been

Stamping Workshop Max O2500-L

Due to the risk of work-related injuries, limited space, and inaccurate docking, this stamping workshop brought in twenty-two Max O2500-L AMRs. With the help of

Leading Car Manufacturer

Workers use PDAs to direct Lynx series AMRs to pick up and tow material carts between different points in the facility. At the line side,

A Leading Roof System Manufacturer

Global Leading Roof System Manufacturer Solution At this roof system manufacturing facility, five of ForwardX’s MAX-1500L AMRs handle material transport across multiple production line stations.

Global Leading Tire Manufacturer

At this tire manufacturing facility, nine of ForwardX’s customized Apex 2000 autonomous forklifts manage raw material delivery to eight production lines. The Apex have been

Automotive Seat & Electric Supplier

After the client’s WMS issues an order, a Flex series AMR goes to the picking area. There, a worker picks the goods according to a

Automotive Parts Manufacturer

A worker issues tasks on a PDA, which are then dispatched to a Flex series AMR via the management system. The AMR travels to pick

Automotive Decoration Manufacturer

After the client’s MES generates task orders, the Flex series AMR picks up a material cart according to the specified pick-up point information. Next, the

Automotive Electronics Manufacturer

In this solution, workers can issue two task types via PDA. One option is to have the AMR carry the full cart from a designated

Well-Known Food Manufacturer

A global leader in the food industry collaborated with ForwardX Robotics to optimize intralogistics material handling, ensuring the delivery of trusted food products worldwide. To

YASKAWA Robotic Arm Integration

Fifteen Flex series AMRs with RFID technology are an integral part of the integrated solution. These AMRs are customized to be compatible with the material

ABB Autonomous Forklift

The Apex autonomous forklifts perform pallet handoff between floors. with the number of Apex split evenly between the top and bottom floors. ABB’s robotic arm

TCL 5G Smart Factory

Max 600-L AMRs are assigned to pick empty pallets and take them to the designated picking points. Here, the AMRs collaborate with human workers who

Multi-Floor Material Transport

To tackle labor shortages, frequent production line changes, and the challenges that come with a facility outfitted with elevators, this company opted for a Flex

Beverage Company Material Handling

Tasks are allocated to a Max AMR. Tasks include fetching empty pallets from the robotic arm and transferring them to the loading area, moving materials

Library Multi-Floor Material Movement

The library WCS system or the librarian’s PDA generates the task order for book delivery and the AMR automatically drives to the docking area in

Automotive: DongFeng Welding Workshop with Flex and Max AMRs

To avoid high-intensity, error-prone, and dangerous labor practices in this automotive welding shop, Dongfeng sought a solution requiring ForwardX’s Flex and Max series AMRs. Workers

E-commerce:Gaatu with Max 600-L

https://www.youtube.com/watch?v=u7cgpR1QrvA Gaatu’s Solution: With 10 Max 600-L AMRs, ShipSage automated its case picking operations across inbound, picking, and outbound zones at its Tracy, California warehouse.

Retail: Highline Warren with Flex 300-SCB

https://youtu.be/lHHE8-b09-c Highline Warren’s Solution With 20 Flex 300-SCB AMRs, Highline Warren streamlined its order fulfillment process. AMRs begin at the induct station, where operators scan

Well-Known Food Manufacturer

A global leader in the food industry collaborated with ForwardX Robotics to optimize intralogistics material handling, ensuring the delivery of trusted food products worldwide. To

Global Leading Tire Manufacturer

At this tire manufacturing facility, nine of ForwardX’s customized Apex 2000 autonomous forklifts manage raw material delivery to eight production lines. The Apex have been

Stamping Workshop Max O2500-L

Due to the risk of work-related injuries, limited space, and inaccurate docking, this stamping workshop brought in twenty-two Max O2500-L AMRs. With the help of

Retail: Highline Warren with Flex 300-SCB

https://youtu.be/lHHE8-b09-c Highline Warren’s Solution With 20 Flex 300-SCB AMRs, Highline Warren streamlined its order fulfillment process. AMRs begin at the induct station, where operators scan

Leading Activewear Provider

Fifteen Flex series AMRs with RFID technology are an integral part of the integrated solution. These AMRs are customized to be compatible with the material

LI & FUNG ECommerce Warehouse

In this intralogistics scenario, eight Flex 300 AMRs outfitted with a conveyor top module receive tasks from the company’s WCS and integrate with conveyors in

SF DHL Coffee Distribution

DHL partner, SF Supply Chain China, is the leading supply chain service provider in China. It currently has warehousing and logistics facilities in more than

ITOCHU Logistics Corporation

With complex workflows, a high error rate, fluctuating seasonal demand, and the high cost of recruitment and training, ITOCHU worked with ForwardX to come up

JD Cosmetics Warehouse

The cosmetics warehouse suffered from high labor and recruitment costs, complex workflows, and high order volume. JD.com and ForwardX devised a solution using ForwardX’s overhead

Kelun Pharmaceutical

Three Apex 1400-L autonomous forklifts were implemented to streamline the outbound process. Running at all hours with the help of opportunistic charging, the autonomous forklifts

Beverage Company Material Handling

Tasks are allocated to a Max AMR. Tasks include fetching empty pallets from the robotic arm and transferring them to the loading area, moving materials

Schneider Electric Components

According to the latest material order in Schneider Electric’s VMS system, the Flex AMR will pick up a full material cart and transfer it to

L’Oréal Autonomous Forklift

Working with Max series AMRs, the Apex 1400-L autonomous forklift completes inbound logistics and assists in picking processes. It also operates with pinpoint precision and

JD Beverage Warehouse Cross Docking

To eliminate the need for storage and expedite the process of material transfer from the 3PL to other businesses, Apex series autonomous forklifts are utilized for

L’Oréal Cosmetics Warehouse

ForwardX successfully deployed over 10 Max AMRs in the group’s Suzhou warehouse to realize an intelligent person-to-goods picking solution. The picking area is about 53,800

Automotive: DongFeng Welding Workshop with Flex and Max AMRs

To avoid high-intensity, error-prone, and dangerous labor practices in this automotive welding shop, Dongfeng sought a solution requiring ForwardX’s Flex and Max series AMRs. Workers

E-commerce:Gaatu with Max 600-L

https://www.youtube.com/watch?v=u7cgpR1QrvA Gaatu’s Solution: With 10 Max 600-L AMRs, ShipSage automated its case picking operations across inbound, picking, and outbound zones at its Tracy, California warehouse.

Retail: Highline Warren with Flex 300-SCB

https://youtu.be/lHHE8-b09-c Highline Warren’s Solution With 20 Flex 300-SCB AMRs, Highline Warren streamlined its order fulfillment process. AMRs begin at the induct station, where operators scan

Well-Known Food Manufacturer

A global leader in the food industry collaborated with ForwardX Robotics to optimize intralogistics material handling, ensuring the delivery of trusted food products worldwide. To

Global Leading Tire Manufacturer

At this tire manufacturing facility, nine of ForwardX’s customized Apex 2000 autonomous forklifts manage raw material delivery to eight production lines. The Apex have been

Stamping Workshop Max O2500-L

Due to the risk of work-related injuries, limited space, and inaccurate docking, this stamping workshop brought in twenty-two Max O2500-L AMRs. With the help of

Stamping Workshop Max O2500-L

Due to the risk of work-related injuries, limited space, and inaccurate docking, this stamping workshop brought in twenty-two Max O2500-L AMRs. With the help of

Kelun Pharmaceutical

Three Apex 1400-L autonomous forklifts were implemented to streamline the outbound process. Running at all hours with the help of opportunistic charging, the autonomous forklifts

YASKAWA Robotic Arm Integration

Fifteen Flex series AMRs with RFID technology are an integral part of the integrated solution. These AMRs are customized to be compatible with the material

Beverage Company Material Handling

Tasks are allocated to a Max AMR. Tasks include fetching empty pallets from the robotic arm and transferring them to the loading area, moving materials

AiHuiShou Full Integration

In this intralogistics scenario, eight Flex 300 AMRs outfitted with a conveyor top module receive tasks from the company’s WCS and integrate with conveyors in

Library Multi-Floor Material Movement

The library WCS system or the librarian’s PDA generates the task order for book delivery and the AMR automatically drives to the docking area in

Automotive: DongFeng Welding Workshop with Flex and Max AMRs

To avoid high-intensity, error-prone, and dangerous labor practices in this automotive welding shop, Dongfeng sought a solution requiring ForwardX’s Flex and Max series AMRs. Workers

Chery Ordos

In Ordos, China, Chery Automotive has partnered with ForwardX Robotics to revolutionize their manufacturing processes at the new Chery Ordos Factory. This state-of-the-art facility features

E-commerce:Gaatu with Max 600-L

https://www.youtube.com/watch?v=u7cgpR1QrvA Gaatu’s Solution: With 10 Max 600-L AMRs, ShipSage automated its case picking operations across inbound, picking, and outbound zones at its Tracy, California warehouse.

Retail: Highline Warren with Flex 300-SCB

https://youtu.be/lHHE8-b09-c Highline Warren’s Solution With 20 Flex 300-SCB AMRs, Highline Warren streamlined its order fulfillment process. AMRs begin at the induct station, where operators scan

Well-Known Food Manufacturer

A global leader in the food industry collaborated with ForwardX Robotics to optimize intralogistics material handling, ensuring the delivery of trusted food products worldwide. To

Global Leading Tire Manufacturer

At this tire manufacturing facility, nine of ForwardX’s customized Apex 2000 autonomous forklifts manage raw material delivery to eight production lines. The Apex have been

Well-Known Food Manufacturer

A global leader in the food industry collaborated with ForwardX Robotics to optimize intralogistics material handling, ensuring the delivery of trusted food products worldwide. To

Global Leading Tire Manufacturer

At this tire manufacturing facility, nine of ForwardX’s customized Apex 2000 autonomous forklifts manage raw material delivery to eight production lines. The Apex have been

Kelun Pharmaceutical

Three Apex 1400-L autonomous forklifts were implemented to streamline the outbound process. Running at all hours with the help of opportunistic charging, the autonomous forklifts

ABB Autonomous Forklift

The Apex autonomous forklifts perform pallet handoff between floors. with the number of Apex split evenly between the top and bottom floors. ABB’s robotic arm

Autonomous Forklift Truck Docking

In this scenario, the Apex autonomous forklift picks up and transports loaded pallets from a staging area before transferring them onto the truck for loading

L’Oréal Autonomous Forklift

Working with Max series AMRs, the Apex 1400-L autonomous forklift completes inbound logistics and assists in picking processes. It also operates with pinpoint precision and

Automotive: DongFeng Welding Workshop with Flex and Max AMRs

To avoid high-intensity, error-prone, and dangerous labor practices in this automotive welding shop, Dongfeng sought a solution requiring ForwardX’s Flex and Max series AMRs. Workers

Chery Ordos

In Ordos, China, Chery Automotive has partnered with ForwardX Robotics to revolutionize their manufacturing processes at the new Chery Ordos Factory. This state-of-the-art facility features

Retail: Highline Warren with Flex 300-SCB

https://youtu.be/lHHE8-b09-c Highline Warren’s Solution With 20 Flex 300-SCB AMRs, Highline Warren streamlined its order fulfillment process. AMRs begin at the induct station, where operators scan

YASKAWA Robotic Arm Integration

Fifteen Flex series AMRs with RFID technology are an integral part of the integrated solution. These AMRs are customized to be compatible with the material

Leading Activewear Provider

Fifteen Flex series AMRs with RFID technology are an integral part of the integrated solution. These AMRs are customized to be compatible with the material

TCL 5G Smart Factory

Max 600-L AMRs are assigned to pick empty pallets and take them to the designated picking points. Here, the AMRs collaborate with human workers who

Automotive: DongFeng Welding Workshop with Flex and Max AMRs

To avoid high-intensity, error-prone, and dangerous labor practices in this automotive welding shop, Dongfeng sought a solution requiring ForwardX’s Flex and Max series AMRs. Workers

Chery Ordos

In Ordos, China, Chery Automotive has partnered with ForwardX Robotics to revolutionize their manufacturing processes at the new Chery Ordos Factory. This state-of-the-art facility features

E-commerce:Gaatu with Max 600-L

https://www.youtube.com/watch?v=u7cgpR1QrvA Gaatu’s Solution: With 10 Max 600-L AMRs, ShipSage automated its case picking operations across inbound, picking, and outbound zones at its Tracy, California warehouse.

Stamping Workshop Max O2500-L

Due to the risk of work-related injuries, limited space, and inaccurate docking, this stamping workshop brought in twenty-two Max O2500-L AMRs. With the help of

Beverage Company Material Handling

Tasks are allocated to a Max AMR. Tasks include fetching empty pallets from the robotic arm and transferring them to the loading area, moving materials

ShipSage by Gaatu

Max 600-L AMRs are assigned to pick empty pallets and take them to the designated picking points. Here, the AMRs collaborate with human workers who

Leading Car Manufacturer

Workers use PDAs to direct Lynx series AMRs to pick up and tow material carts between different points in the facility. At the line side,

Automotive Manufacturer Welding Shop

When the call box is ready, the dispatch system generates the task and assigns it to a Lynx AMR through ForwardX’s Edge Robot Management System

Dongfeng Motor QingShan (Lynx)

At this vehicle manufacturing facility, fourteen Lynx U1000 and six Lynx O1500 towing AMRs ensure minimal downtime and a smooth manufacturing process. With the help

Chery Super One Factory

In the assembly workshop, various component types and a plethora of production tasks made for a challenging environment. ForwardX AMRs were deployed to address these

Chery Super Two Factory

Workers wait in the material distribution area to fill the empty racks the Lynx U1000 AMRs are towing over. The workers accurately pick materials with

Global Leader in Pump Solutions

Lynx O1500 tugging AMRs transport rolling racks at the global leader’s heavy pump assembly line. A customized liftable platform is affixed to the racks, which