Pallet Movement Solution

Intelligent Material Handling with Significant Operational Cost Savings

Trends and Challenges

Pallet transportation has long been a task done by manual forklifts and pallet trucks. But, with rising concern over safety and forklift driver recruitment, autonomous mobile robots offer a viable alternative at a lower lifetime cost. Injuries in the warehouse and factory should be a thing of the past and autonomous material movement a fixture of the future.

Redefining Efficiency and StreaMlining Your Operations

2-3x

UPH INCREASE

99.99%

PICKING ACCURACY

5-9 Months

ROI

1 Month

RAPID DEPLOYMENT

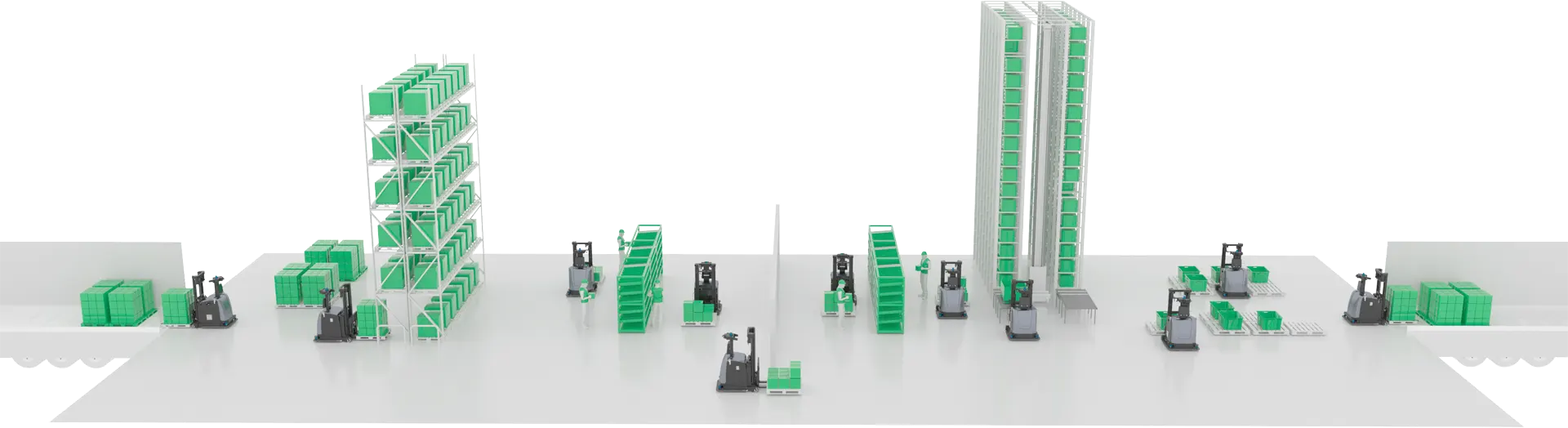

Covering Your Full Transport Journey

World’s Largest Cosmetics Company

Central Warehouse

After realizing immediate results using ForwardX Max 600-L AMRs, the warehouse also introduced the Apex 1400-L autonomous forklift. The project marked the first successful AMR and autonomous forklift operation.

2.36 in

Pallet Placement Precision

1st

AMR & Autonomous Forklift Collaboration

ISO Certified

Safety Tests Meet ISO 13849 Standards

Our Mission

Using our AMRs and deep learning software algorithms, our mission is to add value to people’s lives and businesses’ operations. We envision a future where a network of intelligent robots enhances human potential and allows businesses to become the best employers they can be.