Point-to-Point Transport Solution

Intelligent Material Handling with Significant Operational Cost Savings

Trends and Challenges

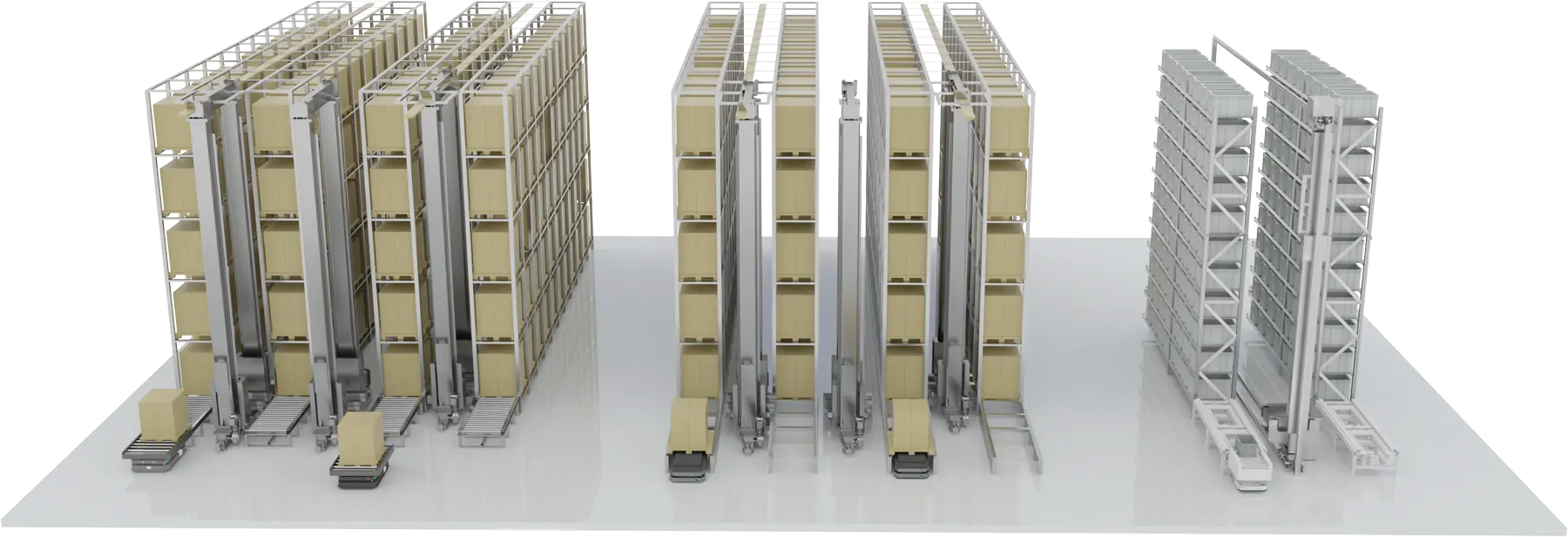

As warehouses look to improve on their existing systems, they need flexible solutions that can be integrated with their existing equipment. Traditional manual processes are labor-intensive, inefficient, and unconducive to visual data management. AMRs docking with automated storage and retrieval systems (AS/RS) effectively solve these major pain points.

Redefining Efficiency and Streamlining Your Operations

2-3x

UPH INCREASE

99.99%

PICKING ACCURACY

5-9 Months

ROI

1 Month

RAPID DEPLOYMENT

Transport Modes

Chong YunXing Supply Chain

Pet Food Warehouse

China’s largest pet food supplier chose a ForwardX conveyor solution to reduce work intensity for its employees and enhance productivity and morale via human-machine collaboration.

2

Flex 300-S

5

Max 600-L

NARROW PASSAGE

HUMAN-MACHINE COLLABORATION

AiHuiShou

3C Product Recycling Plant

AiHuiShou needed a flexible solution that could keep up with its high frequency of production line changes. It also was seeking to reduce operational costs and labor intensity with a solution that could safely work with both humans and machines in narrow aisles.

±0.2 in

Precision Docking

54,000

SQ FT WAREHOUSE

FULLY INTEGRATED

WITH ITS VARIOUS AUTOMATION EQUIPMENT

Our Mission

Using our AMRs and deep learning software algorithms, our mission is to add value to people’s lives and businesses’ operations. We envision a future where a network of intelligent robots enhances human potential and allows businesses to become the best employers they can be.