Imagine a bustling manufacturing floor where humans and robots work seamlessly together, optimizing resources and enhancing productivity—this is today’s reality, driven by advanced autonomous mobile robots (AMRs) and cutting-edge technology. According to the 2023 World Manufacturing Report, the collaboration between robotics and humans has significantly optimized resource utilization, leading to smarter systems for planning and scheduling.

In today’s manufacturing landscape, challenges such as rising labor costs, fluctuating market demands, safety issues, and rapid technological advancements are ever-present. Manufacturers require solutions that not only address these issues but also provide long-term benefits. This is where ForwardX Robotics steps in, offering a wide variety of products and smart solutions.

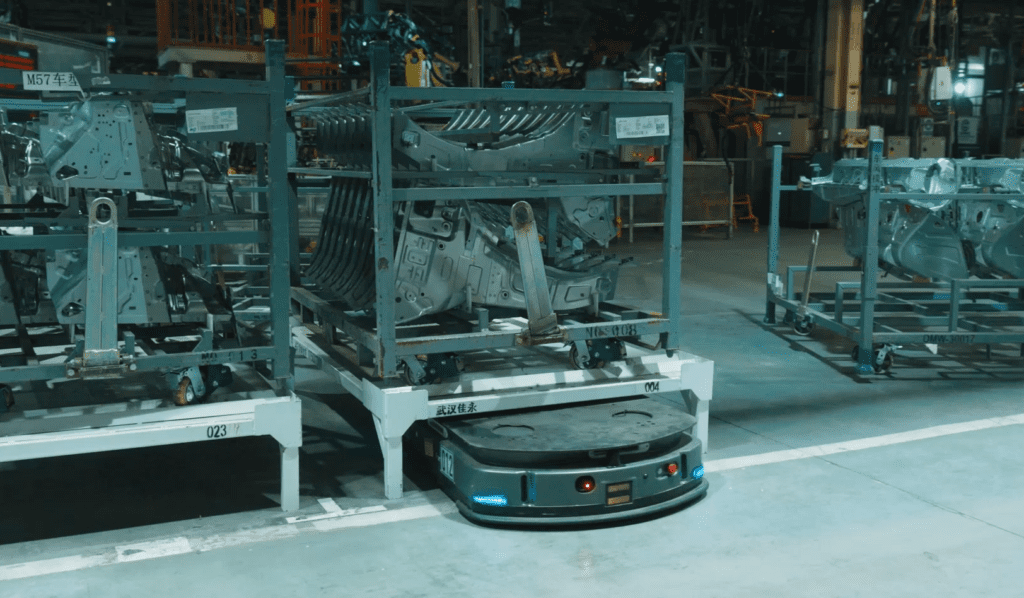

ForwardX Robotics’ Lynx 01500 Tugger AMR Pulling A Train of Carts

Challenge 1: Labor Costs and Shortages

As economies grow, labor costs rise, particularly in developed and emerging countries, exacerbating the shortage of skilled labor—a significant bottleneck for the manufacturing industry. While automation and intelligence can solve this problem, traditional automation equipment can be expensive and inflexible.

Our Solution: ForwardX Robotics’ AMRs and autonomous forklifts reduce reliance on manual labor and boost productivity through efficient autonomous navigation and flexible task scheduling. Our AMRs enable lean manufacturing by performing point-to-point transportation and delivering materials directly to production and assembly lines. This precise delivery method meets the JIT needs of most manufacturing facilities, including the direct delivery of large materials to the production line, which is challenging with manual labor. Our cost effective solution eliminates the fatigue associated with human labor, while ensuring precise, accurate material movement.

ForwardX Robotics’ Max 1500-L Slim AMR Line-Side Delivery

Challenge 2: Safe & Reliable Automation

Manufacturing environments often involve heavy machinery, moving parts, and hazardous materials, posing risks of accidents and injuries. Especially when it comes to automating certain workflows, ensuring a safe work environment is paramount.

Our Solution: Our AMRs and autonomous forklifts are equipped with advanced safety features to minimize these risks. Equipped with state-of-the-art cameras and LiDAR sensors, our robots can recognize obstacles, including human workers and other machinery, in real time. This advanced recognition capability allows the AMRs to navigate the factory floor safely and efficiently, significantly reducing the risk of collisions and injuries.

Moreover, our AMRs are designed for reliability and minimal downtime, crucial for maintaining a productive working environment. Frequent equipment failures not only disrupt production but also increase the likelihood of accidents. By ensuring our robots operate with high reliability, we help maintain a stable and safe production environment

ForwardX Robotic’s Customized Apex 2000 Autonomous Forklift Handling Odd-Sized Pallet

Challenge 3: Fluctuating Manufacturing Needs

Market demand for products varies seasonally, necessitating manufacturers to maintain flexible production capacities.

Our Solution: Our systems seamlessly integrate with existing setups, offering dense storage solutions and an open interface for data integration, visualization, and lean production management. The f(x) fleet manager system intelligently assigns and schedules production tasks, enabling businesses to quickly adapt production plans and improve market responsiveness. By organizing orders intelligently and generating optimal operational routes, our solutions enable manufacturers to adapt rapidly to changing production needs without the high costs of traditional automation.

ForwardX Robotics’ Flex 300-L AMR Line-Side Delivery

The future of manufacturing is brimming with challenges and opportunities. ForwardX Robotics, with its cutting-edge autonomous mobile robot technology, offers innovative solutions to address labor costs, changing market demands, safety concerns, and technological advancements.

Contact us to discover how we can help you overcome these challenges and propel your business forward.