Introduction

In the world of automotive manufacturing, increasing efficiency is more crucial than ever. As automotive Original Equipment Manufacturers (OEMs) strive to maintain efficiency with increasing demands and less workers, they often encounter significant challenges that can hinder their progress. Fortunately, ForwardX Robotics offers proven solutions that address these pain points head-on. Enter the Lynx U1000 and Lynx O1500 Autonomous Mobile Robots (AMRs), two towing AMRs designed to revolutionize the way automotive OEMs operate, bringing unprecedented efficiency and flexibility to the production floor.

Material Handling

Problem: Inefficient Material Handling

Running an automotive OEM operation comes with a unique set of challenges. From managing complex supply chains to ensuring quality control and optimizing production timelines, the difficulties are endless. One of the most pressing pain points is the inefficiency in material handling and logistics within the factory. Traditional methods often rely on manual labor or outdated automated systems that are both inflexible and prone to errors. Additionally, the ever-changing demands of the automotive industry require solutions that can adapt quickly and efficiently without compromising on precision or safety.

Solutions: Lynx U1000

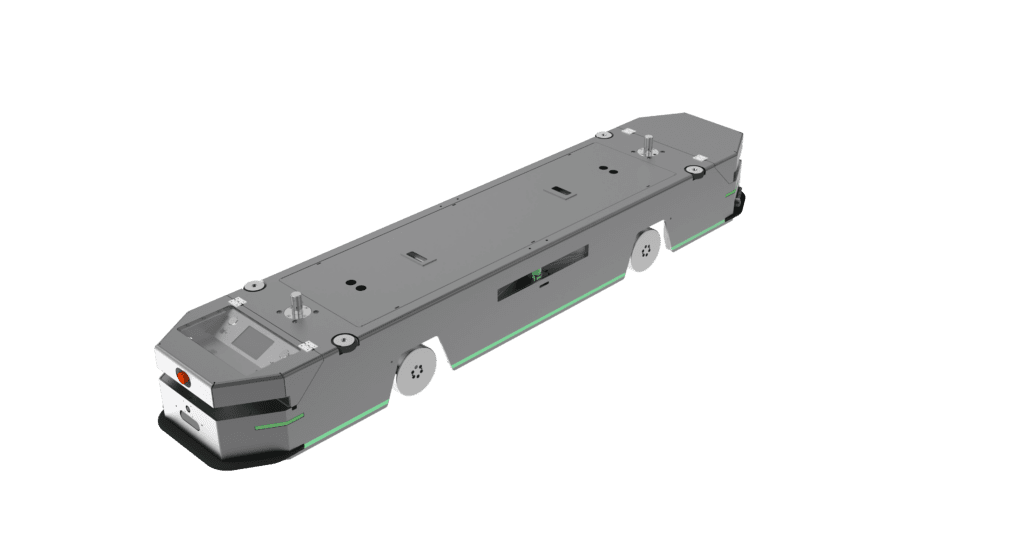

Here’s where ForwardX Robotics’ Lynx U1000 AMR comes into play. The Lynx U1000 is designed specifically to tackle the inefficiencies of material handling that plague many automotive OEMs. This AMR excels in transporting heavy loads—up to 1000 kg (2204 lbs)—with remarkable precision, ensuring that materials are delivered exactly where they need to be with just-in-time (JIT) delivery.

What makes the Lynx U1000 stand out is its advanced AI-powered navigation system. It can maneuver through crowded factory floors, avoiding obstacles, and adjusting its route in real-time to ensure timely deliveries. The result? A significant reduction in delays and human errors, boosting overall productivity. Additionally, its modular design allows for easy integration into existing systems, making it a versatile solution for any automotive OEM looking to upgrade their operations.

Parts & Components Variety

Problem: Parts & Components Transportation

Material handling isn’t the only challenge automotive OEMs face. There’s also the issue of managing a wide variety of parts and components that need to be transported across large manufacturing sites. These parts range in size, shape, and fragility, requiring a flexible yet robust solution that can handle them all without causing damage or delays. The traditional methods, which often rely on conveyor belts or forklifts, lack the adaptability needed to keep up with the dynamic nature of automotive production.

Solution: Lynx O1500

Enter the Lynx O1500 AMR, another solution from ForwardX Robotics that’s tailored to address these specific pain points. The Lynx O1500 is built to transport even larger loads—up to 1500 kg (3306 lbs)— making it ideal for handling a wide array of automotive components. What sets this AMR apart is its movement capabilities, as it can move omni-directionally, and the ability to handle diverse payloads of varying dimensions. Additionally, its compatibility with various racks ensures that every part reaches its destination in perfect condition.

Equipped with an innovative combination of deep learning computer vision, camera, and sensor fusion, the Lynx O1500 navigates complex environments with ease, even in the presence of humans and other moving vehicles. Its flexibility and intelligence make it an indispensable asset for automotive OEMs looking to streamline their logistics and reduce downtime. Plus, like the Lynx U1000, the Lynx O1500 integrates smoothly with existing production systems, ensuring a hassle-free upgrade to your operations.

Lynx U1000 & Lynx O1500 AMR Solutions

In an industry where every second counts, ForwardX Robotics’ Lynx U1000 and Lynx O1500 AMRs provide automotive OEMs with the solutions they need to stay competitive. By addressing critical pain points such as inefficient material handling and the management of complex logistics, these AMRs enhance productivity, reduce errors, and ultimately improve the bottom line.

Ready to revolutionize your automotive OEM operations? Don’t wait—reach out to ForwardX Robotics today and discover how the Lynx U1000 and Lynx O1500 can transform your production floor. With these advanced AMRs on your side, you’ll not only meet the demands of today’s automotive industry but also pave the way for a more efficient and innovative future.

Contact us to learn how we can help you customize your operations while significantly reducing costs.