You see Apex2000G redefine what is possible in warehouse automation. Case picking remains one of the most demanding workflows in logistics. You face challenges when handling Euro and mesh box pallets, and you require systems that adapt quickly. The automated warehouse picking market continues to expand, reaching over USD 22 billion in 2026, and you need technology that keeps pace. Intelligent orchestration now sets a new standard for future-ready operations.

Key Takeaways

- • Apex2000G uses autonomous forklifts to enhance case picking accuracy and speed, allowing workers to focus on higher-value tasks.

- • The closed-loop case picking process integrates all steps into one automated flow, reducing errors and improving efficiency.

- • Real-time scheduling and orchestration optimize resource allocation, leading to faster task completion and fewer bottlenecks.

- • Human-robot collaboration increases productivity and reduces physical strain on workers, creating a safer and more efficient work environment.

- • Investing in automation like Apex2000G can future-proof your warehouse, ensuring adaptability to changing market demands and improving overall operational efficiency.

Apex2000G and Case Picking Automation

Image Source: pexels

Autonomous Forklift Innovation

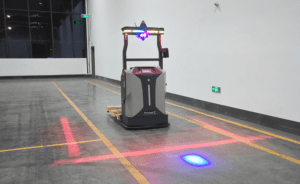

You face constant pressure to improve accuracy and speed in case picking. The Apex2000G introduces a new standard in automation by using autonomous forklifts designed specifically for pallet-based case picking. These forklifts do more than transport pallets. They synchronize with your operators and picking stations, creating a seamless workflow that minimizes errors and maximizes throughput.

You benefit from user-friendly interfaces that display sequenced pick lists with SKU images, quantities, and tote information. This helps your team quickly locate and validate SKUs, reducing mistakes and maintaining high accuracy in picking. Autonomous forklifts automate hazardous and inefficient tasks, allowing your workers to focus on higher-value activities. Smart forklifts optimize task selection and route planning, which reduces unnecessary travel and boosts operational efficiency. This directly improves picking accuracy and overall productivity.

Safety remains a top priority in your warehouse. Autonomous forklifts deliver significant improvements in material handling safety. You see comprehensive sensor coverage that eliminates blind spots and ensures consistent adherence to speed limits and safety zones. The predictable behavior of these forklifts allows your team to anticipate movements, reducing the risk of accidents. Immediate responses to unexpected obstacles or personnel further enhance safety.

| Safety Metric | Improvement Percentage |

|---|---|

| Reduction in material handling incidents | 70-90% |

Autonomous forklifts use advanced obstacle detection and avoidance systems. These systems monitor surroundings continuously, identify obstacles ahead, reduce speed when objects are nearby, and halt movement if an obstacle is directly in the path. You gain confidence knowing your warehouse operates with fewer incidents and greater protection for your staff.

Closed-Loop Case Picking Process

You encounter challenges when managing fragmented workflows in traditional case picking. The Apex2000G restructures these activities into a closed-loop process, integrating pallet handling, picking support, and transport into a single automated flow. This approach eliminates workflow fragmentation and enables stable automation in dense, mixed-operation environments.

You see clear advantages when comparing manual and automated case picking methods:

| Method | Advantages | Disadvantages |

|---|---|---|

| Manual Case Picking | Flexibility, Lower Initial Costs, Human oversight in delicate items | Slower, Higher risk of errors |

| Automated Case Picking | Boost Efficiency, Consistency and Accuracy, Reduced Labor Costs | Higher initial investment, Less flexibility |

Automated storage and retrieval systems (ASRS) significantly reduce manual labor and minimize picking errors. You can collaborate with third-party logistics providers to improve efficiency through advanced warehouse management solutions. The closed-loop process ensures that every step, from pallet selection to order fulfillment, operates under intelligent orchestration.

You benefit from real-time orchestration that dynamically allocates resources, leading to faster task completion. The system reduces travel time and wait cycles, enhancing overall efficiency. Continuous monitoring of warehouse health enables real-time adjustments, so urgent orders receive priority by reallocating the most efficient pickers or equipment. The system predicts bottlenecks before they affect throughput, minimizing errors and maintaining high standards in case picking.

You handle multiple pallet formats, including Euro and GMA pallets, within one automated system. This flexibility allows you to scale your operations without disruption. The Apex2000G adapts to your existing workflows and supports diverse pallet standards, making automation practical and future-ready.

• Tip: You can future-proof your warehouse by choosing automation solutions that support multiple pallet formats and intelligent orchestration. This ensures your operations remain agile and scalable as market demands evolve.

Warehouse Automation Challenges in 2026

Labor and Workflow Complexity

You face mounting labor challenges as you plan for the future of warehouse automation. Rising labor costs continue to impact your bottom line. High turnover rates, often exceeding 40%, make recruitment and retention difficult. The available pool of workers shrinks each year, especially as immigration slows. You must adapt quickly to these changes to maintain efficient operations.

- • Rising labor costs driven by shortages

- • Turnover rates above 40% complicate staffing

- • Fewer available workers due to reduced immigration

You see companies increasingly rely on automation to address these issues. Automated case picking systems help you reduce the need for seasonal hiring, which often proves inefficient and costly. Automation also lowers peak staffing requirements, easing the burden of hiring and training new employees.

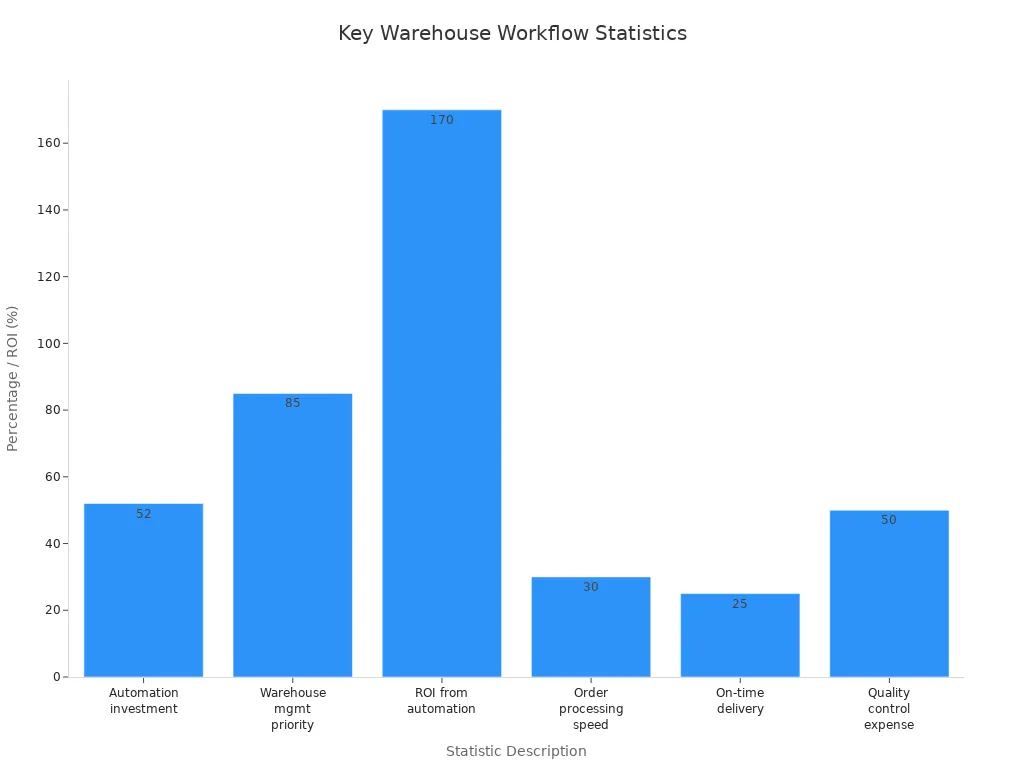

Workflow complexity in your warehouse grows as you manage more orders and SKUs. You invest in automation to keep pace with demand and improve operational efficiency. The following table highlights key statistics that illustrate this trend:

| Statistic Description | Value | Impact |

|---|---|---|

| Increase in automation investment | 52% of facilities | Reflects recognition of automation’s returns and challenges |

| Warehouse management as top priority | 85% of companies | Indicates strategic importance of inventory management |

| ROI from automation | 170-219% over 3 years | Highlights financial benefits of automation |

| Order processing speed increase | 30% faster | Enhances customer satisfaction and throughput |

| On-time delivery improvement | 25% | Correlates with customer retention and satisfaction |

| Quality control expense reduction | 50% | Reduces costs and mitigates compliance risks |

Manual case picking creates bottlenecks that slow your operations. Outdated inventory tracking systems cause inefficiencies in 62% of warehouses. Inventory management delays lead to discrepancies and overstocking. You need substantial storage space for pallets, which limits flexibility in smaller facilities. Order picking costs account for up to 50% of your operating expenses. Shipping and receiving inefficiencies further delay order fulfillment and impact customer satisfaction.

Pallet Diversity and Scalability

You encounter significant challenges as you manage diverse pallet formats in your warehouse. ISO 18613 compliance can reduce product damage by 15% during shipping. Sustainability remains a top priority, with 72% of companies focusing on eco-friendly procurement. Businesses that adopt circular economy principles save about 28% on costs.

Scalability becomes crucial as you implement automated case picking solutions. Case picking works best for large quantities, but you must also handle smaller or mixed orders. Integration with other picking methods, such as piece picking, helps you meet diverse customer requirements. Automated storage systems and third-party logistics providers face challenges due to varying order sizes, so you need scalable solutions.

- • Case picking most effective for large quantities

- • Integration with piece picking essential for flexibility

- • Increased order volumes during peak periods create picking challenges

- • Rigid processes can lengthen order fulfillment times

- • Effective resource allocation needed for high-demand periods

You must balance pallet diversity and scalability to future-proof your warehouse automation strategy. Flexible systems allow you to adapt quickly to changing market demands and customer expectations.

Apex2000G Features for Future Trends

F(x) Software Platform

You need a platform that adapts to the rapid pace of warehouse automation trends. The F(x) software platform gives you this flexibility. It uses the RDS WES-WCS solution, which connects seamlessly with your existing Warehouse Management Systems (WMS) and ERP systems. This integration enhances your automation technology and ensures you do not need to overhaul your current infrastructure.

- • The F(x) platform interfaces with all major WMS and ERP systems.

- • It supports real-time data exchange for accurate inventory and order management.

- • You gain a unified view of your warehouse operations, making it easier to respond to new trends and customer demands.

Real-Time Scheduling and Orchestration

You want to maximize throughput and minimize errors in your warehouse. Real-time scheduling and orchestration help you achieve these goals. The Apex2000G leverages advanced scheduling to optimize every step of the case picking process.

| Evidence Point | Description |

|---|---|

| Reduced Bottlenecks | Scheduling smooths out peaks and valleys in truck arrivals, preventing overwhelming or underutilized docks. |

| Faster Processing Cycles | Scheduled arrivals ensure resources are ready, minimizing loading/unloading time for each truck. |

| Optimized Resource Allocation | Advance scheduling allows for better alignment of labor and equipment with demand, enhancing productivity. |

| Minimized Dock Idle Time | Keeping dock doors occupied with productive work increases throughput significantly. |

You see fewer bottlenecks and faster processing cycles. Real-time orchestration also reduces errors in case picking.

| Aspect | Contribution to Error Reduction |

|---|---|

| Operational Efficiency | Achieves 99% accuracy and reduces manual handoffs, minimizing errors in case picking processes. |

| Enhanced Decision Quality | Leverages comprehensive data to improve decision-making, reducing errors from human judgment. |

| Scalability and Flexibility | Allows real-time adjustments to workload, preventing errors during volume spikes. |

You can adjust to volume spikes and changing order profiles without sacrificing accuracy. These features keep you ahead of warehouse automation trends.

Human–Robot Collaboration

You benefit when humans and robots work together. Human–robot collaboration in the Apex2000G system increases productivity by 24.3% and generates up to 33.4% more revenue for logistics operations. Operators experience up to 90% less muscle tension, which reduces the risk of musculoskeletal disorders.

- • You save up to 34.2% in logistics costs.

- • You can focus on higher-value tasks, while robots handle repetitive or strenuous work.

- • You see improved ergonomics and less pace-related stress.

Human–robot collaboration also supports positive workplace trends. During health crises, collaborative robots help maintain operational efficiency and address health concerns.

The paper discusses the duality of AI’s impact on employee happiness with a focus on how an AI tool impacts indices of happiness including job satisfaction, stress, productivity, morale, and work-life balance. While AI is positive in reducing job tasks related to routine work, increasing mental health support, optimizing workloads, and the possibility for personalization in learning and career development, they also cause employees to be concerned about job security (with layoffs), being surveilled more (using AI styles tracking), and less opportunities for human to human contact. The article maintains that AI can change hostile environments if used properly, that are not only more efficient but also more humane, inclusive, and fulfilling.

You create a more humane and fulfilling work environment by adopting these collaboration models. This approach aligns with the latest trends in warehouse management and employee satisfaction.

Benefits Over Traditional Case Picking

Throughput and Efficiency Gains

You want to stay ahead of the top warehouse automation trends. The Apex2000G gives you a clear advantage in throughput and efficiency. You see your warehouse operate at a higher pace because the system works around the clock. You do not need to worry about shift changes or fatigue. Automated case picking lets you process more orders in less time. You can handle peak demand without hiring extra staff.

You notice that your team spends less time walking and searching for items. The Apex2000G optimizes every route and task. You get faster order fulfillment and fewer delays. This matches the direction of top warehouse automation trends, where speed and reliability matter most. You also see that your system adapts to changing order profiles. You do not need to stop operations for reprogramming. The Apex2000G uses real-time data to adjust on the fly.

You achieve higher accuracy in every pick. The system reduces human error and maintains consistent performance. You can trust that each order meets your quality standards. Top warehouse automation trends show that accuracy is now a key metric for success. You see fewer returns and complaints from customers. This boosts your reputation and keeps your clients satisfied.

You also benefit from lower long-term labor costs. Automated systems reduce your reliance on seasonal workers. You can allocate your staff to higher-value tasks. This aligns with top warehouse automation trends, where companies focus on workforce optimization and technology adoption.

• You can future-proof your business by investing in solutions that deliver both speed and accuracy. This approach keeps you competitive as top warehouse automation trends evolve.

Safety and Space Utilization

You need a safe and organized warehouse. The Apex2000G helps you achieve this goal. Automated forklifts follow strict safety protocols. You see fewer accidents and injuries on the floor. The system uses sensors to detect obstacles and stop when needed. This creates a safer environment for your team.

You also improve space utilization. Automated case picking systems let you store more inventory in less space. You can design narrower aisles and higher racks. This gives you more room for growth. Top warehouse automation trends highlight the importance of maximizing every square foot. You can expand your operations without moving to a larger facility.

The following table compares manual and automated case picking systems. You can see how each method impacts your warehouse:

| Feature | Manual Case Picking | Automated Case Picking |

|---|---|---|

| Flexibility | Adapts quickly to changes in inventory | Less flexible, requires programming changes |

| Initial Costs | Lower upfront investment | Higher initial investment |

| Efficiency | Dependent on human labor | Continuous operation boosts productivity |

| Accuracy | Subject to human error | High consistency and accuracy |

| Labor Costs | Higher long-term labor costs | Reduced labor costs over time |

| Handling of Items | Better for delicate or irregular items | May require specialized equipment |

You notice that automated case picking delivers higher accuracy and efficiency. You also see reduced labor costs and better use of space. These benefits match the direction of top warehouse automation trends. You can scale your business and meet new challenges with confidence.

• Tip: You can use automated systems to improve both safety and space utilization. This strategy supports your long-term growth and aligns with top warehouse automation trends.

Market Growth and ROI Trends

You operate in a market that continues to expand. The robotic picking market is projected to grow from USD 22.04 billion in 2026 to USD 39.38 billion by 2032. This represents a compound annual growth rate of 9.93%. You see more companies investing in automated warehouse picking as data-driven forecasting becomes essential for staying competitive. The future of the robotic picking market depends on your ability to use data for smarter decisions and efficient operations.

When you evaluate investments in warehouse automation, you rely on clear ROI benchmarks. You use metrics such as NPV, IRR, and ROI to measure financial and qualitative returns. These metrics help you understand the impact of your investment on labor costs, service levels, and long-term market positioning.

| Metric | Description |

|---|---|

| NPV | Accounts for the time value of money, providing a clear financial impact of the investment. A positive NPV indicates a viable investment. |

| IRR | Expresses the return as a percentage, indicating financial viability if it exceeds the company’s hurdle rate. |

| ROI | Measures both financial returns and qualitative benefits, including labor cost reductions and improved service levels. |

You can use data from your robotic systems to track these metrics and adjust your strategy. The future of the robotic picking market will reward those who use data for forecasting and continuous improvement.

Practical Guidance for Warehouse Operators

Adoption Considerations

You want to ensure a smooth transition when evaluating automation technology for your warehouse. Start by assessing your current workflows and identifying areas where automation can deliver the most value. Review your warehouse management systems to confirm compatibility with new solutions. Consider how faster adoption of case picking can help you meet customer demands and reduce labor costs.

- • Analyze your order profiles and pallet diversity.

- • Evaluate your current staffing levels and turnover rates.

- • Identify bottlenecks that limit throughput or accuracy.

You should also look at modern warehousing trends and automation trends to benchmark your facility against industry standards. Calculate potential automation investments by estimating labor savings, increased throughput, and improved safety. Use data-driven automation to support your decision-making process.

• Tip: Engage your IT and operations teams early in the adoption process to ensure seamless integration and minimize disruptions.

Implementation Best Practices

You can maximize the benefits of Apex2000G by following proven best practices during implementation. Begin with a pilot program in a controlled area of your warehouse. This approach allows you to test system performance and train your team without impacting daily operations.

- • Set clear goals for throughput, accuracy, and safety.

- • Use advanced warehouse management to monitor progress and adjust workflows.

- • Integrate ai-driven demand forecasting to optimize inventory and picking schedules.

Track key performance indicators to measure ROI and support end-to-end supply chain visibility. Regularly review system data to identify opportunities for continuous improvement.

| Step | Action Item |

|---|---|

| Pilot Launch | Test in a limited area, gather feedback |

| Staff Training | Provide hands-on training for operators |

| System Integration | Connect with existing warehouse management systems |

| Performance Tracking | Monitor KPIs and adjust as needed |

You will see the greatest success when you align your automation strategy with your business goals and industry benchmarks.

You see Apex2000G set a new benchmark for case picking automation. The system gives you flexibility to handle diverse pallet formats and the scalability to grow with your business. You future-proof your warehouse by adopting technology that adapts to changing demands.

• Consider Apex2000G if you want to boost efficiency, improve safety, and stay ahead in warehouse automation. You gain a reliable partner for next-generation operations.

FAQ

What makes Apex2000G different from other warehouse automation solutions?

You gain a system designed for case picking, not just pallet transport. Apex2000G uses advanced technology to support multiple pallet formats and real-time orchestration. This technology helps you automate complex workflows and adapt to changing warehouse needs.

Can Apex2000G integrate with my current warehouse management system?

Yes, you can connect Apex2000G to your existing WMS. The technology behind the F(x) software platform ensures seamless integration. You do not need to replace your current systems to benefit from this technology.

How does Apex2000G improve safety in my warehouse?

You see improved safety through technology-driven sensors and automation. The system uses technology to detect obstacles, follow safety protocols, and reduce accidents. Your team works in a safer environment with fewer risks.

Is Apex2000G scalable for growing operations?

You can scale your operations easily with this technology. Apex2000G adapts to increased order volumes and supports diverse pallet types. The technology allows you to expand without major workflow changes.

What support and training do I receive with Apex2000G?

You receive comprehensive support and training. The technology includes user-friendly interfaces and step-by-step guides. Your team learns to use the technology quickly, ensuring smooth adoption and ongoing success.

• Tip: You can contact the support team anytime for help with technology updates or troubleshooting.