Pallet Movement Solution

Intelligent Material Handling with Significant Operational Cost Savings

Trends and Challenges

Pallet transportation has long been a task done by manual forklifts and pallet trucks. But, with rising concern over safety and forklift driver recruitment, autonomous mobile robots offer a viable alternative at a lower lifetime cost. Injuries in the warehouse and factory should be a thing of the past and autonomous material movement a fixture of the future.

Redefining Efficiency and StreaMlining Your Operations

2-3X

UPH Increase

99.99%

Picking Accuracy

5-9

Month ROI

1 Month

Rapid Deployment

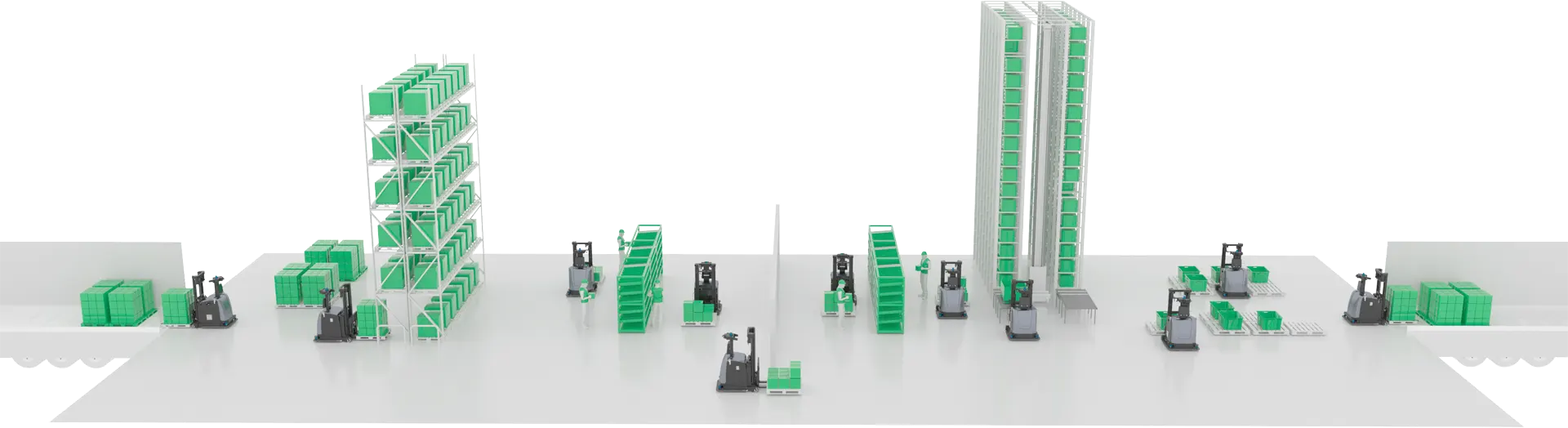

Covering Your Full Transport Journey

Omni Fleet

Your Complete Material Handling Suite

World's Largest Cosmetics Company Cosmetics Warehouse

After realizing immediate results using ForwardX Max 600-L AMRs, the warehouse also introduced the Apex 1400-L autonomous forklift. The project marked the first successful AMR and autonomous forklift operation.