Automotive Manufacturing

OEM

Super One Factory

Super Two Factory

Chery Kaifeng Factory

Chery

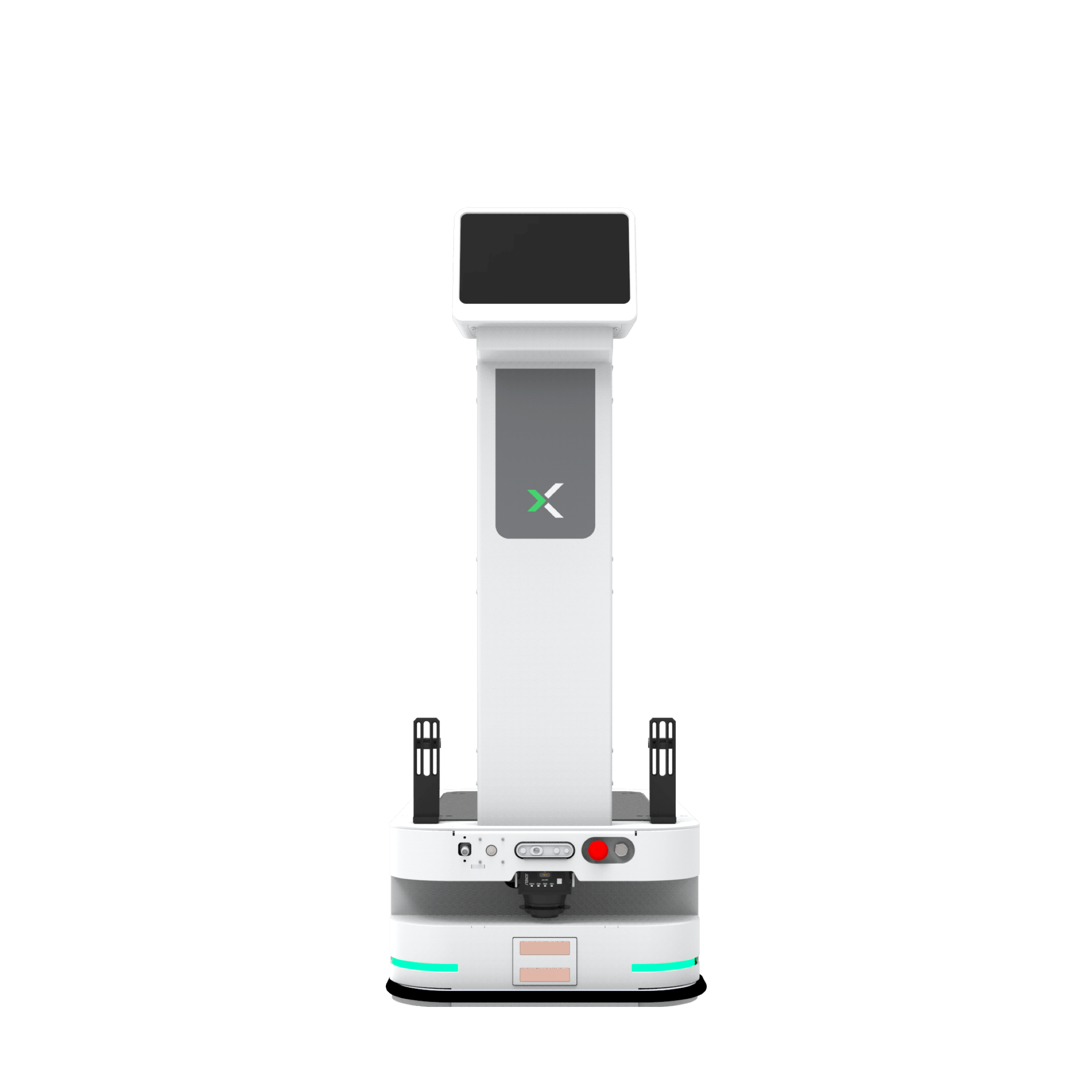

ForwardX deployed 87 Lynx AMRs in the Super Two factory for fully autonomous material transfer in the welding line, 98 Max and Lynx AMRs in Kaifeng for flexible hybrid production, and 400+ AMRs—including 195 Flex, 226 Max, and Lynx U1000—in Dalian to automate warehouse and assembly line logistics.

In total, over 700 AMRs have been deployed across Chery’s facilities, driving JIT delivery, enhanced safety, and accelerated production.

Seres

In stamping workshops, safety risks, tight spaces, and docking accuracy are constant challenges. The Max O2500-L is built to handle ultra-large racks while integrating seamlessly with the MES. With real-time data synchronization, it enables predictive management of both stamping line production and AMR logistics, ensuring a safer and more efficient workshop.

Welding workshops often struggle with forklift congestion, manual material handling, and the need for precise material delivery. ForwardX AMRs solve these challenges by automating the entire intralogistics process — from material reception and storage to just-in-time delivery and empty rack recycling. With intelligent route optimization and ±10mm precision docking, our AMRs enable seamless integration with robotic arms and welding stations, achieving zero forklifts, zero manual handling, and a safer, more efficient workshop.