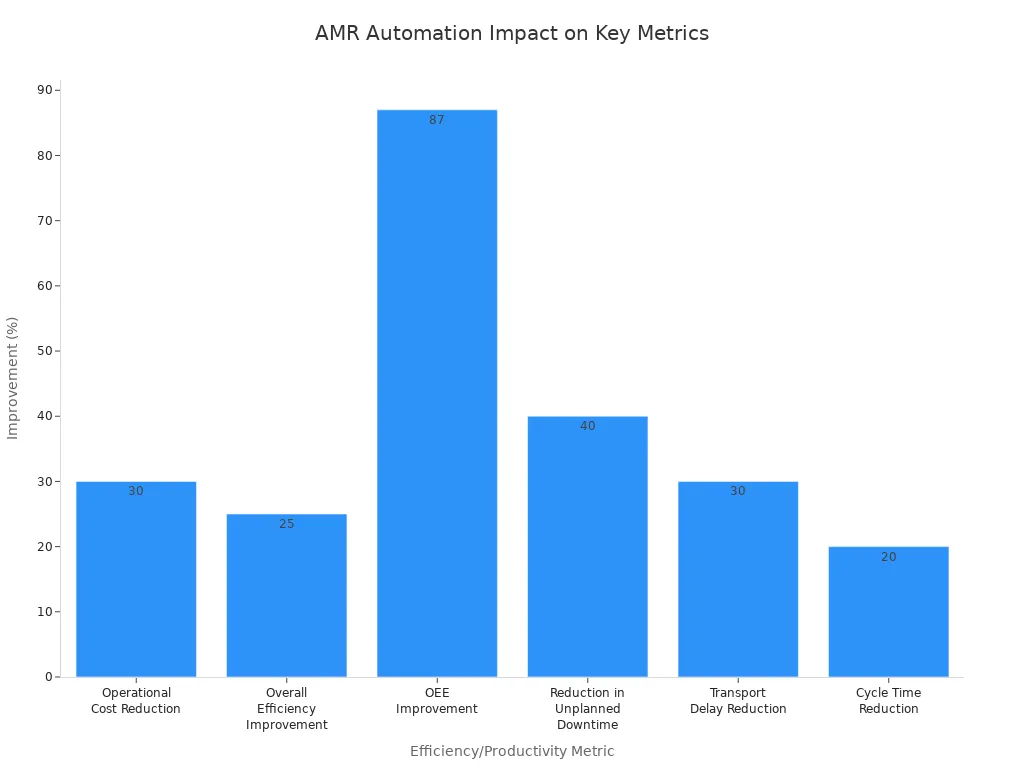

AMR automation is quickly changing how cars are made. Robots now move materials in factories. This helps keep workers safe and speeds up the work. You can see this in places like stamping workshop in Seres and BYD battery workshop. More than half of car factories use AMR systems for material handling. The market for these robots may reach USD 3.1 billion by 2030. It is growing by about 17% each year. Companies like Chery trust automation to make work better and safer. Look at the table below to see how amr technology helps car factories:

|

Metric |

Impact |

|---|---|

|

Operational Cost Reduction |

|

|

Overall Efficiency Improvement |

25% |

|

OEE Improvement |

Up to 87% in highly automated plants |

|

Reduction in Unplanned Downtime |

40% (Ford’s implementation) |

|

Transport Delay Reduction |

30% (AMR-PLC synchronization) |

|

Cycle Time Reduction |

15-20% (Volkswagen’s implementation) |

Stay ahead of the curve with the latest robots, such as the Max 1500-L and Max O2500-L. Built with advanced safety features and versatile handling capabilities, these robots enhance efficiency and flexibility across the production line.

Key Takeaways

-

AMR automation is changing how cars are made. It makes factories safer and more efficient. Factories with AMRs can cut costs by up to 30%.

-

AMRs are flexible and learn new jobs fast. This helps factories change layouts or products easily. They do not need to stop work for long.

-

AMRs let workers do harder tasks. Robots do the heavy lifting and boring jobs. This makes the workplace safer for everyone.

-

AMRs collect data to help run factories better. This data shows where things are slow. It helps make the whole factory work faster.

-

Using AMRs can save a lot of money. Factories often get their money back in 12 to 18 months.

AMR Basics in Automotive

What Are AMRs?

Autonomous Mobile Robots (AMRs) are now a common sight in many car factories. They transport parts and tools to keep production lines running smoothly. Equipped with advanced sensors and intelligent software, AMRs navigate safely without colliding with people or machinery. They handle tasks such as delivering parts, supplying lines, and removing waste, helping factories operate more efficiently.

Here are some main jobs AMRs do in automotive factories:

-

Material transport: AMRs bring parts and tools to work stations. This helps stop delays.

-

Assembly line assistance: They keep parts moving to the lines. This is important when the factory is busy.

-

Palletizing: AMRs pack products fast and with care.

-

Inventory management: They update stock records right away. This stops things from running out.

-

Production line feeding: AMRs bring parts just when needed. This means you do not need big storage rooms.

-

Tool retrieval: Robots get tools for workers.

-

Waste removal: AMRs help clean up waste quickly.

Some AMRs, such as the Max 1500-L and Max O2500-L, come with advanced capabilities. The Max 1500-L can lift and transport up to 3,300 pounds, making it ideal for case picking and pallet handling. The Max O2500-L can tow loads of up to 5,500 pounds in any direction, improving safety and efficiency in tight spaces. Both models integrate with warehouse systems and provide real-time updates, showcasing how AMRs are transforming automotive factories.

Advantages Over Traditional Automation

AMRs give you many good things compared to old systems. AMRs can change jobs and paths fast. You can reprogram them or change their routes easily. You do not need to change the whole factory. This helps you keep up with new needs.

Here is a table that compares AMRs and old systems:

|

Feature |

AMRs |

Traditional Systems |

|---|---|---|

|

Scalability |

Needs big changes to the factory |

|

|

Operational Flexibility |

Can change jobs or paths fast |

Not easy to change because paths are set |

Some people think AMRs cost a lot or take jobs. But AMRs let workers do better jobs. You can set up AMRs in about a month. Big car companies like Chery use these robots. ForwardX AMRs made moving parts 40% faster and cut labor costs by 30% in the welding shop. This proves robots help car factories grow and work better.

Automation Trends in Automotive Production

Flexibility and Adaptability

Automotive manufacturing is undergoing a major shift from single-purpose machines to flexible, multi-functional automation. AMRs play a critical role in this transition, offering adaptability to evolving production requirements. Unlike traditional guided systems with fixed routes, AMRs leverage advanced sensor technology and cloud-based intelligence to dynamically navigate the factory floor. This capability enables manufacturers to reconfigure layouts, scale operations, and introduce new products with greater speed and efficiency.

ForwardX makes powerful AMRs like the Max 1500-L and Max O2500-L. The Max 1500-L can carry up to 3,300 pounds, while the Max O2500-L can handle loads of up to 5,500 pounds. Both robots move safely around obstacles and work well in tight spaces. They support key processes such as assembly, welding, and stamping. For example:

-

Chery Dalian uses 435 AMRs in final assembly. This helps move materials and lowers labor.

-

Dongfeng’s welding shop uses ForwardX AMRs. They make welding safer and faster.

-

Seres Auto’s stamping shop uses 22 Max O2500 AMRs. This makes work safer and more exact.

These robots help factories work better and keep up with changes in car making.

Tip: Flexible robots help you change fast and stay ahead in the market.

Logistics and Material Transport

Moving parts and tools is very important in car factories. AMRs make this job easier and safer. They carry things across the factory without people helping. This lowers accidents and lets workers do harder jobs.

New AMRs from ForwardX can carry heavy loads and find their way easily. Max O2500-L can pull big loads in any direction. This is good for busy workshops. Other robots, like Seegrid’s Lift RS1 and Boston Dynamics’ Stretch, show how much robots have improved. They lift heavy things and work for long hours.

Here are some good things about using AMRs for moving stuff:

-

Scalability: You can add or change robots when you need.

-

Safety: Sensors stop crashes and keep people safe.

-

Productivity: Robots do simple jobs so workers can do more important work.

-

Flexibility: AMRs can change paths and help with inventory fast.

AMRs work with people too. Robots move things while workers build or check quality. As robots get cheaper, more car factories use them to stay ahead.

|

Trend |

Description |

|---|---|

|

Collaborative Robots (Cobots) |

Cobots help people by doing simple jobs and keeping them safe. |

|

Edge Computing PLCs |

Fast data checks help fix problems before they stop work. |

|

Modular and Integrated SCADA |

Flexible systems let you see and control work in real time. |

|

Advanced Human-Machine Interfaces |

Easy screens help workers make fewer mistakes and learn faster. |

|

Robotic Simulation |

Testing robot jobs on computers stops work from being interrupted. |

|

Energy-Efficient Automation |

Saves energy and helps the environment. |

ForwardX AMR does very well in car factories. Here are some numbers:

|

Metric |

ForwardX AMR |

|---|---|

|

Logistics Cost Reduction |

10% |

|

Line-side Over-supply Rate |

<15% |

|

Assembly Error Rate |

<0.002% |

|

Material Preparation Efficiency |

200% increase |

Using AMRs helps your company be greener. Robots lower pollution, save energy, and cut waste. Stellantis uses AMRs to move heavy or dangerous things safely. This shows robots help keep people safe and protect the planet.

Note: Using more robots makes your car factory work better and helps the environment.

Smart Manufacturing Integration

Industry 4.0 and IoT

Now, robots work together in new ways. In car factories, Industry 4.0 and IoT connect everything. AMRs talk to machines and conveyor belts right away. This makes the line smarter and faster.

Here is how AMRs work with Industry 4.0 and IoT:

|

Aspect |

Description |

|---|---|

|

Real-time Communication |

IoT lets AMRs talk to other systems, like conveyor belts and sorting machines. |

|

Dynamic Task Allocation |

AMRs change jobs and routes based on what is happening now. |

|

Workflow Optimization |

Teamwork between robots cuts slowdowns and helps logistics work better. |

You can use robots like Max 1500-L for picking cases. It can see all around and lift up to 1,500 kg. Max O2500-L can pull heavy things in any direction, even in small spaces. These robots use sensors and AI to move safely. They can change to new paths without help from people. When you connect AMRs to SCADA, you can watch and control your whole factory in one place. This helps you manage robots and keep things running well.

Tip: Data from your robots helps you find problems early and fix them before they slow down your work.

Data-Driven Optimization

You can use robot data to make your factory better. In car factories, AMRs collect info as they work. This data shows where you can save time and do better.

-

An electronics company used data to find slow spots. They made cycle times 15% faster and got 20% more done.

-

In a textiles center, data helped balance work and speed up deliveries by 30%.

-

Ford uses AMRs to bring parts to the line, keeping the floor clear and parts moving.

-

GE Appliances uses robots to deliver parts on time, so production does not stop.

When you use ForwardX AMRs, you get more good results. At Chery’s Dalian Factory, over 400 AMRs move materials just in time. This keeps lines running and lowers mistakes. Max O2500-L can lift big shelves, so it is easier to move large parts. You can trust these robots to keep your car factory safe and working well.

Safety in Automotive Manufacturing Processes

Advanced Sensors and Obstacle Avoidance

You want your car factory to be safe and run well. Robots with special sensors help make this happen. These sensors let AMRs see what is around them and stop accidents. The Mobile Robot Standard R15.08-1-2020 gives rules for using AMRs in car factories. Groups like A3 made these rules to keep workers safe as more robots are used.

AMRs can spot people, machines, and other things in their way. Max 1500-L is made for picking cases. It can see all around and avoid things. It can lift up to 1,500 kg and dock very carefully. Max O2500-L can tow in any direction and work in small spaces. Its strong jack helps move big shelves safely. These features make car production lines safer and more flexible.

Here is how these sensors help stop accidents:

|

Source |

Evidence |

|---|---|

|

Innorobix |

AMRs with better sensors lower accidents and make work safer. |

|

United Robotics |

AMR sensors find obstacles well, so accidents with heavy loads go down. |

|

Innorobix |

AMRs with smart sensors can go around things and keep the workplace safer. |

You can count on these robots to keep your car factory safe and working well.

Human-Robot Collaboration

You now see more robots working with people in automotive factories. This teamwork lets people do creative jobs while robots do boring or risky work. Industry 5.0 says working together with robots is important for safety and getting more done.

The research says working with robots in car assembly is important. It talks about the need for small, strong robots that can learn from people. It also talks about making robots that help lift things and learn new jobs to help workers.

You can follow these tips to make working with robots safe and easy:

-

Help everyone learn what cobots can do and how to stay safe.

-

Keep talking clearly and give good training for safe teamwork.

ForwardX and Chery work together and use over 700 AMRs to help a big automotive company grow. At Chery’s Dalian Factory, AMRs run the warehouse and make work faster. People and robots work together, making car factories safer and better.

Tip: When you train your team and use smart robots, your car factory becomes safer and more flexible.

Implementation Challenges

System Integration

Bringing AMRs into car factories can be hard. Many factories use old and new machines together. It is tricky to make new robots work with old systems. You must connect AMRs to your automation and inventory tools. Old systems may be slow with data. This can cause mistakes or delays. You might get wrong inventory numbers or miss tasks. Fast data is needed for good inventory control. If AMR location data is slow, the line can slow down. Experts say new sensors and better data help fix these issues. Working with skilled integrators makes things easier. They help robots talk to other machines. This keeps your car factory working well.

Workforce Training

Your team needs to learn new skills for AMRs. Many workers know only old ways of working. Using robots can feel strange at first. Car makers help workers learn with training programs. These programs give workers more chances to learn. They help workers get ready for new jobs. Here are some steps you can follow:

-

Work with experts to make a plan for AMRs.

-

Train your staff so everyone feels ready for change.

-

Add AMRs slowly to keep things smooth.

Good training helps your team switch to robots. It also helps workers feel sure about using new tools.

Real-World Impact of AMR Automation

Case Studies in Automotive Manufacturing

Many car factories use autonomous mobile robots. These robots help move materials and make work faster. They also help keep workers safe. Here are some examples:

-

KINEXON OS helps manage robot fleets in plants. You can use robots from different brands together. This makes work faster and more efficient.

-

Grupo Antolin uses robots and cobots to move car parts. All transfers are now automated. This gives more flexibility and makes the workplace safer. Workers can do harder jobs now.

-

Denso put six MiR250 robots in their factory. Before, workers walked up to 12 miles each day. Now, robots do this job and save time and energy. You do not need big changes to use these robots.

-

In Germany, robots changed routes to help the production line. This stopped delays and kept things moving.

-

In the U.S., robots sent parts to the line just in time. This made work smoother and faster.

-

Volkswagen used robots to make their supply chain better. This cut mistakes and let workers focus on quality.

Using robots helps you make your car factory more flexible and efficient.

ForwardX and Chery worked together to use over 700 robots. At Chery’s Dalian Factory, robots changed how materials were moved. Max 1500-L can lift up to 1,500 kg. Max O2500-L can tow up to 2,500 kg. These robots helped reach big goals:

-

Material handling got 40% faster.

-

Labor costs went down by 30%.

-

Assembly got better with fewer mistakes and faster times.

-

Chery sold more cars and set new records.

These results show that ForwardX robots help car factories work better and safer.

Measurable Benefits

You want to know what robots can do for your factory. The benefits are clear and easy to measure. Here are some top results:

-

Robots use smart navigation to avoid mistakes.

-

You can add robots without stopping work or making big changes.

-

Robots change jobs and routes using live data. This stops delays.

-

Some robots use AI to find problems early. You can fix things before they break.

-

Robots move materials to the right place at the right time.

-

Robots bring tools and parts to workers. This makes repairs faster.

-

You can add more robots as your factory grows.

-

Robots work with digital twins to spot and stop slowdowns.

Reports say robots can cut delays by up to 30%. This means you build more cars in less time.

Car factories use more robots than other industries. About 40% of all robots go to car plants. The market for robots is growing fast and may reach $4 billion soon. Companies like BMW and Toyota buy more robots to make work better. In 2023, India sold over 1.5 million electric cars. This shows the need for more automation.

Robots help you work faster and support just-in-time manufacturing. They also work well with automated guided vehicles. This gives you a full solution for your car factory.

When you use robots, you join many companies who use technology to stay ahead.

AMR automation is changing how people work in car factories. Robots like Max 1500-L and Max O2500-L help keep workers safe. They also help everyone get more done each day. Workers can do smarter jobs while robots lift heavy things or do risky work. AMRs help you change quickly when new jobs come up. This keeps your factory ready for anything.

-

Find where moving parts or people is hard.

-

Look at your factory’s setup and what tech you need.

-

Make clear goals and plan how to use robots.

|

Resource |

Description |

|---|---|

|

Overview of AMR in the automotive sector |

|

|

Comprehensive guide for manufacturers |

|

|

Examples of AMR in use |

Keep learning about new AMR trends. Check your work often and use these resources to help your factory stay ahead.

FAQ

How does the Max O2500-L improve production line flexibility?

Max O2500-L can tow loads up to 2,500 kg in any direction. It works well in tight spaces. Its strong jacking system lifts big shelves. You get more flexibility and safety on your production line.

How did ForwardX and Chery work together to boost efficiency?

Chery used over 700 ForwardX AMRs in its factories. In just 12 weeks, material handling speed went up by 40%. Labor costs dropped by 30%. This helped Chery sell more cars and set new records.

Can AMRs work with people safely?

Yes. AMRs use smart sensors to spot people and obstacles. They stop or change direction to avoid accidents. Workers and robots can share the same space safely.

What are the main benefits of using AMRs in car factories?

You get faster material movement, fewer mistakes, and lower costs. AMRs help you change your factory layout quickly. They also keep workers safe and support just-in-time production.