The logistic automation transforme supply chains everywhere. The global market reached USD 35.44 billion in 2023 and will soar to USD 98.77 billion by 2032. Consumers expect fast, convenient delivery, so companies like Successful Chain Store Luckin Coffee and Amazon rely on automation to meet demand. ForwardX Robotics leads this shift by deploying intelligent robots for picking, packing, and delivery. We must consider automation now to stay competitive and keep customers satisfied.

Key Takeaways

-

• Logistics automation is essential for meeting consumer demands for fast and reliable delivery. Companies like Amazon and Luckin Coffee use automation to stay competitive.

-

• Implementing automated systems can boost efficiency by 30-40%, reduce errors, and allow operations to run 24/7, leading to faster order fulfillment.

-

• Automation leads to significant cost savings, with businesses reporting reductions of up to 40% in labor costs and improved return on investment within nine months.

-

• Automated inventory management systems achieve accuracy rates of up to 99.99%, minimizing human error and enhancing customer satisfaction.

-

• Emerging technologies like AI and robotics are transforming logistics, enabling real-time tracking, optimized routes, and sustainable practices.

What is logistic automation

Core concepts

We encounter logistic automation every time when we order a product online and receive it quickly. This approach uses technology to streamline supply chain tasks, making operations faster and more reliable. We are able to see automated inventory management systems tracking stock levels in real time. Robotic process automation handles repetitive tasks, such as order verification and shipment tracking, without human error. Advanced system helps companies select suppliers and assess risks. Transportation management systems optimize delivery routes and track shipments. Automated storage and retrieval systems boost warehouse efficiency. We benefit from improved decision-making because real-time data is always available. End-to-end tracking gives us visibility across the supply chain. Companies scale and adapt to market changes with ease. Automated notifications keep you updated on our order status. Workplace safety improves through monitoring systems, and continuous operation monitoring helps manage risks. Optimized transportation routes also support sustainability initiatives.

-

• Automated inventory management for real-time tracking

-

• Robotic process automation for repetitive tasks

-

• AI for supplier selection and risk assessment

-

• Transportation management systems for route optimization

-

• Automated storage and retrieval systems for warehouse efficiency

-

• Real-time data access for better decisions

-

• End-to-end supply chain visibility

-

• Scalability and flexibility in operations

-

• Automated tracking notifications for customers

-

• Workplace safety improvements

-

• Risk management through continuous monitoring

-

• Sustainability through optimized routes

Key technologies

We find several technologies driving logistics automation. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) play major roles. AGVs operate on fixed routes, guided by magnetic strips or wires. AMRs use sensors and cameras to navigate dynamically. These technologies work in industries such as e-commerce, automotive, pharmaceuticals, and third-party logistics. AGVs reduce manual labor and optimize space use. AMRs offer flexibility and adaptability, improving picking rates and reducing human contact.

|

Technology Type |

Description |

Applications |

Benefits |

|---|---|---|---|

|

Automated Guided Vehicles (AGVs) |

Operate on fixed routes, guided by magnetic strips or wires. |

E-commerce, Automotive, Pharmaceutical, 3PL |

Reduced manual labor, consistent throughput, optimized space use, improved data integration |

|

Autonomous Mobile Robots (AMRs) |

Use sensors and cameras for dynamic navigation. |

E-commerce, Automotive, Pharmaceutical, 3PL |

Flexibility, adaptability, improved picking rates, reduced human contact |

We see AMRs assisting with goods-to-person picking in e-commerce fulfillment. AGVs move bulk-picked goods to shipping areas. In automotive manufacturing, AGVs deliver parts just in time, while AMRs transport kits to workstations. AMRs operate in cleanrooms for pharmaceutical production, reducing contamination risk. Third-party logistics providers use AMRs to handle seasonal peaks and AGVs for repetitive movements.

Robotics, artificial intelligence, and machine learning enhance logistics automation. Robots track and manage warehouse inventory, reducing errors and handling oversized packages efficiently. Robotics increases speed and accuracy in tracking tasks. When integrated with AI and machine learning, robots exchange real-time data, making supply chains smarter. AI algorithms optimize delivery routes and monitor warehouse conditions. Robots learn from experience, improving efficiency over time. You see better route planning and demand estimation. Inventory control improves as AI analyzes historical sales data. Robots perform complex tasks like pick-and-place operations.

Processes involved

We experience logistics automation through several automated processes. Product retrieval uses automated equipment to collect items from storage and place them onto conveyors. Conveyors or AMRs transport goods to pick stations, working safely alongside people and machines. Order assembly sorts items according to orders, often using visual aids or fully automated systems. Warehouse management software coordinates these activities, organizing the flow of goods and enabling continuous order fulfillment.

|

Stage |

Description |

|---|---|

|

Product retrieval |

Automated equipment collects products from storage locations and places them onto conveyors. |

|

Transport to pick stations |

Conveyors or AMRs carry goods to workstations, operating safely alongside people and machines. |

|

Order assembly |

Items are sorted according to orders, often using visual aids or fully automated systems. |

|

Coordination via software |

A WMS manages the operation, organizing the flow of goods and facilitating continuous order fulfillment. |

We see automation revolutionizing order processing and fulfillment. Manual errors disappear, and workflows accelerate. Robotic process automation handles repetitive tasks, such as order verification and shipment tracking. Companies streamline complex processes, reduce manual intervention, and boost overall efficiency. Modern supply chains involve many interconnected stages, from procurement and manufacturing to distribution and delivery. Automation simplifies these steps using robots, software, and real-time data.

Benefits of logistics automation

Efficiency and speed

We experience a dramatic boost in efficiency and speed when we implement logistics automation. Automated systems handle repetitive tasks, such as order picking and inventory updates, much faster than manual labor. Companies using AI in logistics report automating up to 50% of repetitive tasks. We can expect efficiency improvements of 30–40% and a significant reduction in manual labor input.

-

• Automated systems process purchase orders instantly, leading to quicker operations.

-

• We see fewer errors compared to manual processes.

-

• Automation allows you to operate around the clock, so your supply chain never stops.

When you compare traditional manual processes with automated solutions, the difference becomes clear:

|

Evidence Type |

Description |

|---|---|

|

Automated Fulfillment |

Orders are fulfilled with minimal human intervention, enhancing speed. |

|

Continuous Operation |

Automated systems operate 24/7, leading to faster processing times. |

|

Error Reduction |

Automation minimizes human errors, improving order accuracy. |

|

Labor Dependency |

Automation reduces reliance on human labor, addressing workforce challenges. |

|

Increased Throughput |

Automation significantly boosts order processing capabilities. |

ForwardX Robotics takes efficiency to the next level. For example, Highline Warren, a leading automotive distributor, implemented the ForwardX Flex Series AMRs and saw a streamlined picking process. The robots guided operators with LED lights and on-screen instructions, reducing physical strain and improving speed. The company maintained its next-day delivery promise, even during peak seasons.

Cost savings

We save money when you switch to logistics automation. Automated systems cut labor costs, reduce errors, and optimize resource allocation. Businesses in logistics report average cost savings of 30%. In manufacturing, savings reach 25%, while financial services see up to 40% in immediate reductions.

|

Industry |

Average Cost Savings |

Notes |

|---|---|---|

|

Financial Services |

40% |

Immediate cost reductions |

|

Manufacturing |

25% |

Significant efficiency gains |

|

Logistics |

30% |

Proven solution for cost cutting |

|

General RPA Use |

30% to over 70% |

Potential savings exceeding $100 million |

ForwardX Robotics’ product and Flex Series deliver measurable improvements in productivity and ROI. The Flex Series reduces walking time by 60% and labor costs by 50%. We achieve a quick return on investment, often in less than nine months. Automated robots consolidate workflows, so we need fewer workers for the same output. This helps we address recruitment and turnover challenges.

|

Evidence |

Description |

|---|---|

|

Labor Cost Optimization |

Automation offers a pathway to optimize resource utilization and minimize workforce-related expenditures. |

|

Enhanced Operational Efficiency |

Reduces reliance on manual labor and enhances operational efficiency. |

Accuracy and scalability

We gain unmatched accuracy and scalability with logistics automation. Automated inventory management systems achieve accuracy rates of up to 99.99%. We minimize human error, which leads to fewer delays and improved customer satisfaction. Automated systems monitor inventory levels in real time, so we always know when to restock.

|

Improvement Type |

Description |

|---|---|

|

Order Accuracy |

Companies using automated inventory management systems achieve accuracy rates of up to 99.99%. |

|

Reduction in Human Errors |

Automation reduces manual handling errors and data entry mistakes, enhancing operational integrity. |

|

Scalability |

Automated systems can maintain 99.9% uptime, allowing for efficient operations during peak demand. |

ForwardX Robotics solutions, such as the Flex Series, provide precise information on item location and quantity. You see a substantial increase in picking accuracy. The robots operate continuously, so you can scale up during busy periods without hiring extra staff. For example, Highline Warren handled over 4,000 SKUs efficiently, even as order volumes surged.

|

Evidence Point |

Description |

|---|---|

|

Automated Scaling |

Systems can adjust automatically to demand fluctuations. |

|

Real-Time Adaptability |

Systems monitor traffic and adjust resources in real-time. |

|

Cloud-Based Solutions |

Enable rapid scaling of infrastructure without costly hardware upgrades. |

|

Efficient Workflow Tools |

Help prioritize tasks and dynamically assign resources. |

|

Improved Efficiency |

Businesses can handle demand spikes without scrambling. |

|

Enhanced Customer Satisfaction |

Scalable systems lead to reduced wait times. |

|

Reduced Operational Costs |

Streamlined processes reduce the need for manual adjustments. |

|

Increased Employee Satisfaction |

Staff are less likely to experience burnout. |

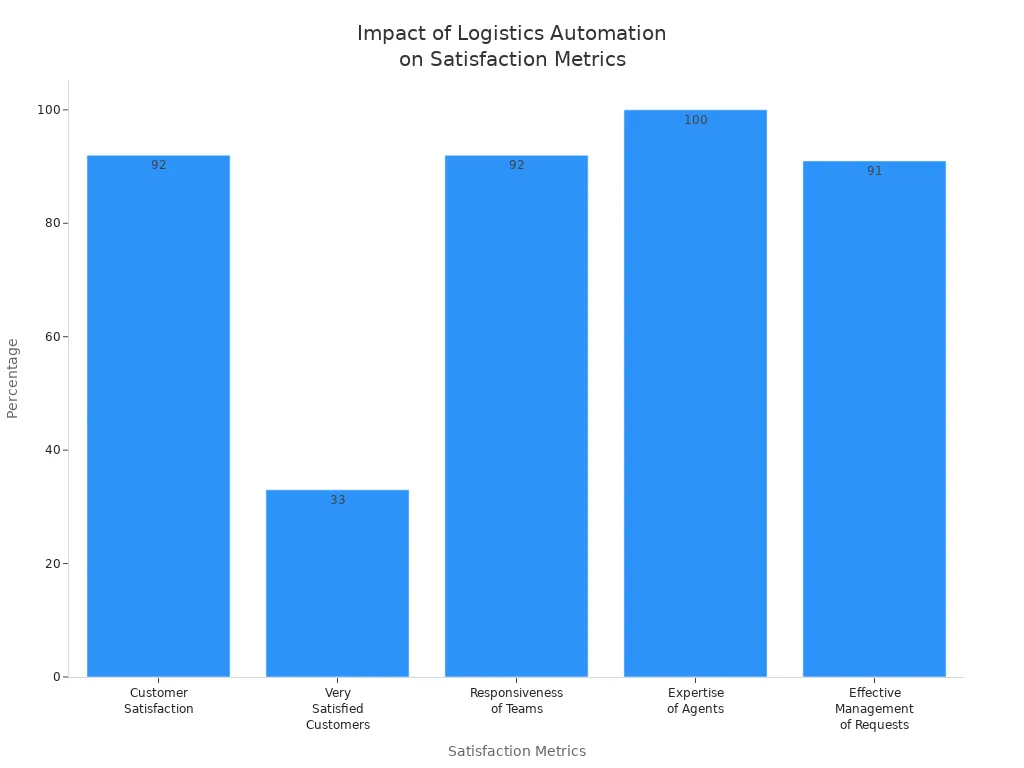

Customer satisfaction

We improve customer satisfaction when you use logistics automation. Fast delivery and high order accuracy keep our customers happy and loyal. Automation reduces human error, so we send the right product every time. Customers expect their orders to arrive quickly, and we meet these expectations with automated systems.

• Fast delivery is a crucial component of customer satisfaction. Customers expect their orders to arrive as quickly as possible, and businesses that can meet these expectations are more likely to retain their customers.

|

Metric |

Percentage |

|---|---|

|

Customer Satisfaction |

92% |

|

Very Satisfied Customers |

33% |

|

Responsiveness of Teams |

92% |

|

Expertise of Agents |

100% |

|

Effective Management of Requests |

91% |

-

• High order accuracy is essential for customer retention and brand credibility.

-

• Incorrect orders can lead to returns and increased costs, negatively impacting customer satisfaction.

-

• Automation reduces human error, enhancing order accuracy.

ForwardX Robotics solutions help you deliver on your promises. Highline Warren maintained its next-day delivery standard, even during peak demand, thanks to the Flex Series AMRs. The robots guided operators, reduced errors, and ensured every order was accurate. You build trust with your customers and strengthen your brand reputation.

• Failure to deliver the correct product on time can severely damage customer experience and business credibility. A single negative experience can lead to a loss of trust, prompting customers to switch to competitors. This highlights the critical importance of maintaining high order accuracy to ensure customer satisfaction.

We see that successful logistics automation transforms your supply chain. We gain speed, save money, scale with ease, and keep our customers satisfied. Solutions like ForwardX Robotics’ Product and Flex Series set a new standard for productivity, accuracy, and ROI in supply chain management.

Applications in logistics

Industry examples

We see logistics automation transforming industries like retail, manufacturing, and e-commerce. Companies use automation to optimize routes, track shipments in real time, and manage inventory efficiently. In warehouses, robots pick and sort orders, reducing errors and speeding up fulfillment. Automated storage systems, such as miniload AS/RS for boxes, help e-commerce businesses retrieve products quickly. Roller conveyors connect different warehouse areas, streamlining storage and dispatch. These technologies improve supply chain efficiency and lower operational costs.

|

Application |

Description |

|---|---|

|

Route Optimization |

AI identifies the most efficient delivery routes, saving time and reducing fuel costs. |

|

Real-Time Tracking |

Sensors on shipments provide real-time updates on their location and condition. |

|

Automated Inventory Management |

Centralized data systems collect and manage inventory, orders, and shipments efficiently. |

|

Warehouse Monitoring |

IoT devices track equipment usage and stock levels for better efficiency. |

|

Robotics |

Autonomous robots assist in picking and sorting orders, enhancing operational efficiency. |

ForwardX Robotics solutions

We can address labor shortages and rising recruitment costs with ForwardX Robotics’ AMRs. These robots use LiDAR sensors and computer vision to navigate complex warehouse environments. We reduce dependency on manual labor and increase productivity. The Flex solution, for example, automates picking and packing workflows. ITOCHU Logistics China used a fleet of Flex 300-R AMRs and the f(x) Fleet Manager software to minimize travel, reduce fatigue, and scale operations quickly. After implementation, ITOCHU saw a 52% reduction in operational costs. You can also use discrete order picking, batch picking, and sorting solutions to handle high order volumes and meet tight deadlines. These solutions help you adapt to seasonal peaks and changing market demands, making your supply chain more resilient.

-

• Labor shortages become manageable with AMRs.

-

• Operational efficiency improves as robots handle repetitive tasks.

-

• Scalability allows you to meet demand during busy periods.

Challenges and considerations

Implementation costs

We face several challenges when you consider logistic automation for your supply chain. The most immediate obstacle is the high upfront investment. We need to purchase equipment, software, and upgrade your infrastructure. These costs can seem overwhelming at first. However, we should look at the long-term benefits. Automation often leads to significant savings over time. We reduce labor costs, improve operational efficiency, and boost customer satisfaction. Many companies find that the return on investment justifies the initial expense. ForwardX Robotics helps you manage costs with flexible options like Robots-as-a-Service (RaaS). This subscription model lets we adopt automation without a large upfront payment, making it easier to upgrade our operations.

|

Challenge |

Description |

|---|---|

|

Upfront Costs |

Significant initial investment for equipment, software, and infrastructure. |

|

Productivity Loss |

Possible reduction in productivity during implementation. |

• Tip: Consider the long-term savings and ROI when evaluating automation investments. Flexible models like RaaS can lower barriers to entry.

Workforce impact

Automation changes the way we manage our workforce. Some roles in supply chain management, such as logistics managers, face high exposure to automation. Over 90% of their tasks can be automated. Other jobs, like bus and truck mechanics, remain unaffected. We see a shift from manual tasks to overseeing and optimizing automated systems. Workers need new skills to stay relevant. We must invest in reskilling and upskilling our team. Automation does not eliminate jobs; it transforms them. Our employees become supervisors and problem-solvers, managing advanced technology instead of performing repetitive tasks.

-

• Automation can lead to resistance from employees who fear job loss.

-

• We need to provide training and support to help our team adapt.

-

• Workers move from manual labor to managing and optimizing automated systems.

Integration issues

We encounter integration challenges when we add automation to your supply chain. Connecting new technology to legacy systems can be difficult. We may face compatibility issues and disruptions. We can address these problems with a clear strategy. Gradual rollouts help we adjust and minimize disruptions. We should communicate openly with our team and stakeholders. Training programs build confidence and skills. Auditing our current systems helps us identify integration points. Middleware solutions, such as API layers, make it easier to connect old and new systems. ForwardX Robotics supports us with localized deployment, multilingual training, and technical support. Their team helps we integrate automation smoothly, ensuring our supply chain management remains efficient.

|

Strategy |

Description |

|---|---|

|

Gradual Rollouts |

Implement new technologies in phases to reduce disruptions. |

|

Clear Communication |

Keep stakeholders informed to build trust and understanding. |

|

Thorough Training |

Provide comprehensive training to enhance employee skills. |

|

Auditing Current Systems |

Assess existing systems for compatibility. |

|

Middleware/API Layers |

Use middleware to connect legacy and new systems. |

|

Integration Tools |

Choose technologies with strong integration capabilities. |

• Note: ForwardX Robotics offers training in multiple languages and ongoing technical support, helping you overcome integration challenges and scale globally.

The future of logistic automation

Emerging trends

We see new trends shaping logistics automation every year. Artificial intelligence now predicts order volumes and optimizes picking routes. Robotics technology enables fully autonomous systems to handle picking, packing, sorting, and last-mile delivery. These robots work without fatigue, which reduces lead times and costs. Sustainability is becoming a central focus. By 2025, companies will use automation to lower environmental impact while maintaining efficiency. Collaborative robots, or cobots, work alongside people to improve productivity and safety. Edge computing allows robots to make decisions in real time, which speeds up tasks like obstacle avoidance and inventory tracking.

|

Trend |

Description |

|---|---|

|

AI predicts order volumes, optimizes picking routes, and forecasts inventory needs for better efficiency. |

|

|

Autonomous systems handle picking, packing, sorting, and delivery, reducing costs and lead times. |

|

|

Collaborative robots |

Cobots assist humans with sorting and packing, improving safety and productivity. |

|

Edge computing |

Robots process data locally for faster decision-making and task execution. |

|

Sustainability |

Automation reduces carbon footprints and optimizes resource use to meet environmental targets. |

Industry evolution

We watch the logistics industry evolve as automation becomes more advanced. Companies like DHL and FedEx have partnered with technology leaders to improve supply chain operations. DHL worked with Locus Robotics to develop robots that boost warehouse efficiency and reduce errors. FedEx joined forces with Microsoft to use AI for supply chain management, which improves real-time tracking and data analysis. You see more businesses adopting automation to streamline supply chain processes and meet customer expectations for speed and accuracy. The industry now relies on data-driven decisions and flexible systems that adapt to changing demands.

-

• DHL partnered with Locus Robotics to enhance warehouse operations and reduce errors.

-

• FedEx collaborated with Microsoft to improve supply chain management using AI and real-time tracking.

-

• Companies invest in automation to meet customer expectations and optimize supply chain performance.

ForwardX Robotics vision

We can see ForwardX Robotics leading the way in logistics automation. The company focuses on enhancing warehouse operations, especially in cold storage environments. Their autonomous mobile robots use advanced vision systems to increase efficiency and accuracy. ForwardX Robotics aligns with industry trends by integrating robotics into supply chain management. We benefit from solutions that support continuous improvement and adaptability. The brand aims to redefine logistics automation, making supply chains smarter and more resilient. We can expect ForwardX Robotics to keep innovating and delivering intelligent automation worldwide.

-

• ForwardX Robotics enhances warehouse operations, including cold storage.

-

• Their AMRs use advanced vision systems for greater efficiency and accuracy.

-

• The company drives the integration of robotics in supply chain management.

-

• You gain access to solutions that support adaptability and continuous improvement.

• Tip: Stay informed about new automation technologies. You can future-proof your supply chain by adopting solutions that align with industry trends.

We see automation changing how you manage your supply chain. Automation streamlines transportation, warehouse, and yard management. We gain efficiency and reduce costs. Robotics, including AGVs and AS/RS systems, optimize operations and provide real-time visibility. Automation improves inventory control and decision-making agility. We benefit from labor savings, cost reduction, and improved customer service. Automation allows our business to scale and support sustainability. We can focus on strategic initiatives and use our team more effectively. The future promises even greater transformation as automation continues to evolve.

-

• Automation enhances safety and efficiency by automating repetitive tasks.

-

• Automation optimizes routing and inventory management for significant savings.

-

• Automation supports growth and eco-friendly practices.

-

• Automation improves customer satisfaction with real-time tracking.

-

We can explore automation to unlock new opportunities and build a resilient supply chain for tomorrow.