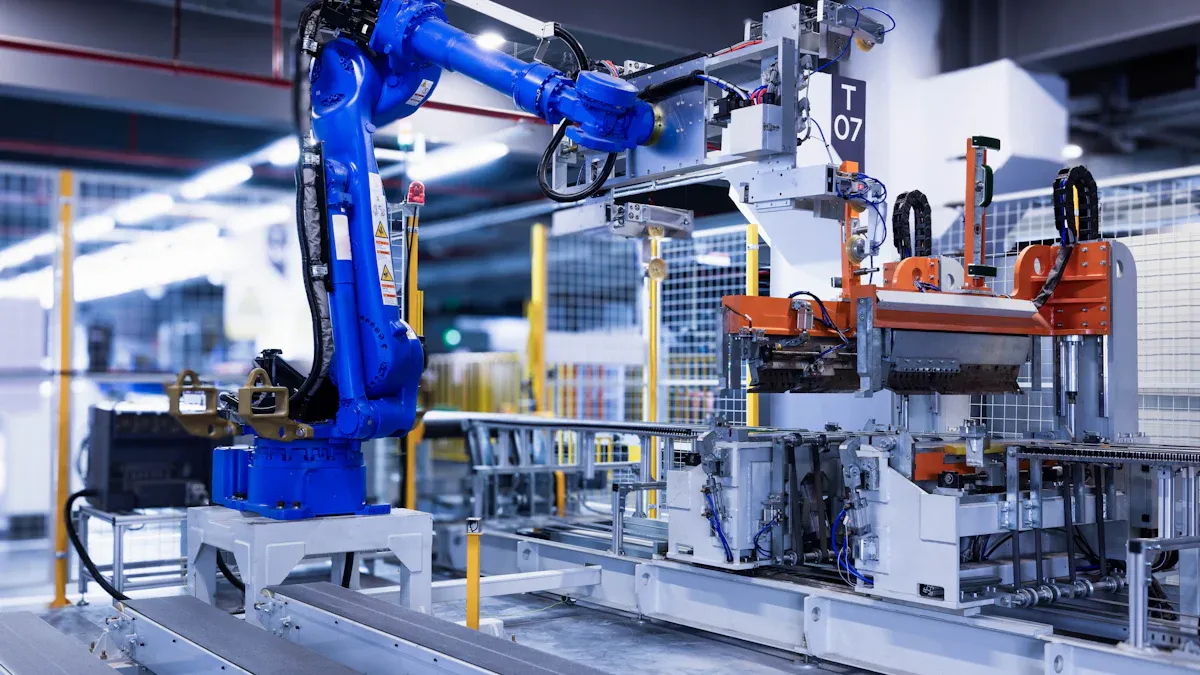

By 2025, experts estimate that half of all warehouses will use automation. Warehouse robotics companies have drastically changed how businesses handle inventory and fulfill orders. Today, automation boosts operational efficiency and improves accuracy in order processing. Many companies dedicate about 25% of capital spending to automation, showing its growing importance.

-

• Robots now work alongside people, allowing workers to shift to more strategic tasks.

-

• Warehouse robotics and automation have also shaped workforce trends, encouraging upskilling and new roles.

Staying aware of these trends helps businesses make informed decisions about warehouse automation companies and future investments.

Key Takeaways

-

• By 2025, half of all warehouses will use automation, enhancing efficiency and accuracy in order processing.

-

• Robots work alongside humans, allowing employees to focus on strategic tasks and increasing job satisfaction.

-

• Investing in warehouse automation can lead to a return on investment within two to three years, making it a smart financial choice.

-

• Real-time inventory tracking with robotics improves accuracy and reduces costs, helping businesses respond quickly to demand changes.

-

• Sustainability efforts in warehouse automation lead to energy savings and reduced waste, supporting corporate responsibility goals.

Warehouse Robotics Evolution

Early Milestones

The journey of warehouse automation began with several important milestones that shaped the industry:

-

• The term ‘robot’ appeared in 1920, introduced by Karel Čapek in his play ‘R.U.R.’ This marked the conceptual start of robotics.

-

• In the 1950s, engineers developed the first true robots for factory use. These early machines laid the foundation for warehouse automation.

-

• General Motors launched the Unimate robot in 1961. This robot automated repetitive tasks in factories and warehouses, setting a new standard for efficiency.

-

• By the 1980s, advances in computers and robotics led to the first robotic arm with motors in its joints. This technology enabled basic warehouse functions and paved the way for modern warehouse robotics.

• Note: These milestones highlight how warehouse automation has evolved from simple machines to complex systems that support modern supply chains.

Key Advances

Since the 2000s, warehouse automation has accelerated due to several technological breakthroughs. The adoption of robotics and AI has grown rapidly in warehouses worldwide. AI and machine learning now allow robots to learn and adapt, which improves operational efficiency and reduces human error. These advances have also increased picking accuracy and reliability.

|

Technological Advance |

Description |

|---|---|

|

Automated the storage and retrieval of goods, transforming warehouse automation. |

|

|

Warehouse Management Software (WMS) |

Improved inventory management and operational efficiency through better data handling. |

|

RFID Technology |

Enhanced tracking and management of inventory, boosting accuracy and efficiency. |

|

Automated Guided Vehicles (AGVs) |

Enabled automated transport of goods, reducing labor costs and increasing speed. |

|

Provided flexibility and adaptability, integrating easily into existing warehouse automation. |

The rise of e-commerce has driven the need for faster and more efficient warehouse automation solutions. Advancements in navigation technology, such as simultaneous localization and mapping (SLAM), have improved the speed and accuracy of AGVs and AMRs. These robots now integrate into existing warehouse automation systems without major infrastructure changes. As a result, warehouse robotics and robotic automation continue to transform the industry, making operations smarter and more responsive.

Warehouse Automation Companies Today

Market Growth

Warehouse automation companies have experienced remarkable growth in recent years. The global warehouse automation market reached an estimated USD 19.23 billion in 2023. Analysts expect this figure to rise sharply, with projections showing the market could reach USD 59.52 billion by 2030. Some forecasts even suggest the market may hit USD 91.0 billion by 2033. This rapid expansion reflects a compound annual growth rate (CAGR) between 15.9% and 18.7% over the next decade.

Several companies lead the warehouse automation sector. These warehouse automation companies drive innovation and set industry standards. New entrants, such as ForwardX Robotics, continue to push the boundaries of robotics and automation, offering advanced solutions for modern warehouses.

• Note: The strong market growth signals a shift in how businesses view warehouse automation. Companies now see automation as a strategic investment rather than a luxury.

Technology Adoption

Warehouse automation companies have introduced a wide range of technologies to meet the needs of modern supply chains. Fortune 500 companies often adopt the following solutions:

-

• Autonomous Mobile Robots (AMRs) transport goods across warehouses without fixed paths.

-

• Automated Storage and Retrieval Systems (ASRS) use robotic shuttles or cranes for high-density storage.

-

• Conveyor systems move packages and pallets between zones.

-

• Automated Guided Vehicles (AGVs) follow set routes to transport goods.

-

• Robotic picking arms use AI to identify and sort items.

-

• Robotic palletizers and depalletizers handle loading and unloading tasks.

-

• Sortation systems automate package sorting.

-

• Vision systems and AI cameras track inventory.

-

• High-reach robotic vehicles access elevated shelving.

Warehouse automation companies report high adoption rates for these technologies. Many businesses invest in automation to improve efficiency and accuracy. However, cost and return on investment remain important considerations. For medium-sized projects, companies often see a return on investment within six to eight years. Larger projects may require up to ten years. Some market analysts note that many companies achieve ROI in as little as two to three years, especially when they deploy scalable solutions.

AI, IoT, and modular robotics play a crucial role in the success of warehouse automation companies. IoT technology provides real-time inventory data and improves maintenance prediction. AI and machine learning optimize warehouse operations by analyzing data and allocating tasks efficiently. Modular robotics allow companies to scale and adapt their systems quickly, making integration with existing infrastructure easier.

-

• IoT devices synchronize inventory information and offer holistic performance visibility.

-

• AI transforms data into actionable insights, reducing errors and improving decision-making.

-

• Modular robotics enable seamless integration and scalability.

Despite these advances, warehouse automation companies face several barriers. Cost and ROI concerns affect 40–44% of businesses. Training and change management present challenges for 43% of companies. Implementation complexity and integration issues also rank high among obstacles.

• Tip: Companies considering warehouse automation should evaluate both the benefits and challenges. Careful planning and a focus on scalable, modular solutions can help maximize ROI and minimize disruption.

Warehouse automation companies continue to shape the future of logistics. Their innovations drive efficiency, accuracy, and flexibility, making warehouse robotics an essential part of modern supply chains.

Operational Impact

Efficiency Gains

Warehouse automation has transformed fulfillment operations by delivering measurable efficiency gains. Companies that deploy robotic automation, such as Goods-to-Person (GTP) systems, see dramatic improvements in order picking. These systems bring products directly to workers, which reduces walking time and allows employees to focus on verifying and packaging orders. This shift leads to faster fulfillment and fewer errors.

ForwardX Robotics and similar companies have helped warehouses achieve the following:

|

Metric |

Improvement |

|---|---|

|

Operational Errors |

|

|

Storage Capacity |

50% increase |

|

Throughput |

2-3x increases |

|

Labor Cost Reduction |

Millions saved |

|

Inventory Accuracy |

Consistently at 99.9% |

|

Operational Errors |

Zero production delays |

Automated systems also enable warehouses to scale up quickly during peak seasons. Managers report that automation trends like AMRs and robotic picking arms accelerate operations, trim labor costs, and enhance productivity. Many logistics managers cite improved safety, higher customer satisfaction, and fast scalability as top benefits.

The financial impact is clear. According to industry studies, companies often achieve a return on investment from warehouse automation in 18–24 months. Some specialized robots, such as those used by Amazon, reach payback in as little as 12 months under a robots-as-a-service model. These rapid payback periods make robotic automation a strategic choice for fulfillment centers seeking long-term cost savings and operational optimization.

Real-Time Inventory Tracking

Real-time inventory tracking stands at the core of modern warehouse automation. Robotics and AI-powered systems provide continuous, real-time updates on stock levels, locations, and movement. This capability supports inventory optimization and ensures that fulfillment teams always know what is available.

|

Evidence Type |

Description |

|---|---|

|

Accuracy Rate |

Robotics in inventory management achieves accuracy rates exceeding 99.5%. |

|

Stock Counting Speed |

Robotics accelerates stock counting processes by up to 60%. |

|

Cost Savings |

Businesses can save up to 25% on inventory carrying costs through robotic solutions. |

Companies that adopt real-time inventory tracking report significant improvements:

-

• A retail client minimized overstock by 20% within six months after implementing robotic technology.

-

• Businesses achieved a 35% reduction in inventory holding costs through precise tracking with AI.

-

• Enhanced order fulfillment accuracy by 25% due to real-time data analytics.

Real-time data enables fulfillment teams to respond quickly to demand changes and avoid costly stockouts or overstock situations. Automation trends in real-time inventory tracking also support better decision-making and proactive management. The integration of AMRs with intelligent software improves coordination between robots and human workers, further boosting speed and accuracy in fulfillment.

Sustainability

Sustainability has become a key focus in warehouse automation. Robotic automation supports energy savings, waste reduction, and emission control. Companies like ForwardX Robotics design solutions that optimize energy use and minimize environmental impact.

|

Sustainability Benefit |

Description |

|---|---|

|

Energy Savings |

Robotic systems optimize tasks, reducing lighting and heating needs, leading to significant energy savings. |

|

Waste Reduction |

AI and machine vision enable real-time monitoring to uncover inefficiencies, limiting waste. |

|

Emission Reduction |

Electric forklifts reduce greenhouse gas emissions compared to traditional gas or diesel options. |

Automation trends show that warehouses using robotic automation can cut utility costs and improve overall energy management. AI-driven systems monitor operations in real-time, uncovering inefficiencies and reducing waste. Electric vehicles and equipment lower greenhouse gas emissions, supporting corporate sustainability goals.

Long-term cost savings also come from sustainability efforts. Automated systems allow facilities to handle increased demand without costly expansions. Employees benefit from safer, less physically demanding roles, which improves retention and job satisfaction. Customers receive reliable, on-time fulfillment, which boosts loyalty and satisfaction.

• Note: Warehouse automation delivers efficiency, accuracy, and sustainability improvements that drive fulfillment success. Real-time optimization and automation trends continue to shape the future of warehouse operations.

Workforce and Safety

Upskilling

Warehouse robotics companies have changed the types of skills employees need. Workers now move from repetitive tasks to more specialized roles. Many employees find greater job satisfaction as they take on new responsibilities. Companies create positions such as robot mechanics and team leads in exception handling areas. These new roles require technical knowledge and problem-solving skills. As a result, warehouses see a drop in employee turnover and higher engagement.

-

• Employees transition from monotonous tasks to skilled roles, which increases job satisfaction.

-

• New positions, including robot mechanics and exception area leads, highlight the need for advanced skills.

-

• The introduction of robots leads to a significant reduction in employee turnover, showing improved retention and engagement.

Upskilling programs help workers adapt to new technology and support career growth.

Cobots and Collaboration

Collaborative robots, or cobots, work alongside humans in many warehouses. These machines handle tasks that require precision and consistency. Workers focus on quality control and decision-making while cobots manage repetitive or heavy tasks. The table below shows common cobot applications in modern warehouses:

|

Application |

Description |

|---|---|

|

Packaging |

Cobots perform packaging tasks while workers check item quality before and after packaging. |

|

Bin Picking |

Cobots sort and select items from bins, improving inventory management and order fulfillment. |

|

Material Handling |

Cobots load, unload, transfer parts, or arrange products for further processing or packaging. |

|

Automated Replenishment |

Cobots help restock shelves or pick items for orders, streamlining the replenishment process. |

Cobots increase productivity and reduce physical strain on workers. Teams benefit from improved workflow and fewer injuries related to heavy lifting.

Safety Improvements

The introduction of robotics in warehouses has brought both benefits and challenges for safety. Some facilities report higher injury rates after adopting robotics. For example, Amazon’s robotic warehouses had a serious injury rate of 7.9 per 100 workers in 2019, which was over 54% higher than non-robotic sites. In Tracy, California, the serious injury rate nearly quadrupled in four years after robots arrived. Studies show a 40% decrease in severe injuries but a 77% increase in non-severe injuries due to automation. Machine malfunctions and poor workstation design can cause repetitive strain injuries. Workers also face increased cognitive strain and pressure to meet productivity targets, which can lead to accidents.

-

• The serious injury rate at Amazon’s robotic facilities was 7.9 per 100 workers in 2019, much higher than at non-robotic facilities.

-

• Reports show a correlation between robots and increased safety problems, with serious injury rates quadrupling in some locations.

-

• Automation led to a 40% decrease in severe injuries but a 77% increase in non-severe injuries.

-

• Machine malfunctions and poor ergonomic design contribute to injuries.

-

• Workers experience more cognitive strain and pressure to meet targets, which can create unsafe conditions.

Companies must balance productivity gains with worker safety by improving workstation design and providing proper training.

Warehouse Trends for 2025

AI and Data Insights

Smart warehouses now rely on advanced AI to drive efficiency and accuracy. In June 2025, new deployments and product releases showcased how AI transforms warehouse operations. Companies use platforms like enVista’s enMotion, which integrates multiple technologies for better distribution center performance. GreyOrange’s GreyMatter orchestrates robot fleets, optimizing workflows. AI forecasts customer demand, manages stock levels, and uses machine learning to improve storage and picking. Predictive maintenance reduces downtime by monitoring equipment health. The table below highlights recent AI-driven developments:

|

Development |

Description |

|---|---|

|

New Deployments |

Warehouses launched advanced AI systems for automation and optimization. |

|

Product Releases |

Companies released tools that use AI for operational efficiency. |

|

Industry Trends |

AI applications now focus on real-time data and process improvement. |

Modularity

Smart warehouses benefit from modular systems that adapt to changing needs. Modular, best-of-breed solutions allow businesses to scale automation without major infrastructure changes. Flexibility enables real-time responses to operational demands. Companies like ForwardX Robotics design flexible systems that support scalable automation and quick adaptation. This trend ensures that smart automation can grow with business requirements.

-

• Modular systems provide adaptability and scalability.

-

• Real-time flexibility supports business growth and changing demands.

-

• Scalable automation reduces the need for costly upgrades.

Robotics-as-a-Service

Robotics as a service has changed how companies approach automation. Facilities now access advanced robotics with lower upfront costs and predictable monthly fees. This model makes scalable automation available to smaller businesses. Cloud-based warehouse management systems support robotics as a service, allowing for easy integration and updates. Companies benefit from improved accuracy, customer satisfaction, and long-term savings.

-

• Predictable costs help businesses plan for growth.

-

• Cloud-based warehouse management systems enable seamless updates.

Cybersecurity

Smart warehouses face new cybersecurity challenges as digitalization increases. Threat actors target logistics operations to disrupt supply chains and steal data. Companies respond by building strong cybersecurity frameworks, including network security and incident response plans. The rise of robotics as a service and constant communication between robots and control systems create new vulnerabilities. Best practices include static code analysis, vulnerability testing, and user authentication. By 2025, cybercrime costs are expected to reach $10.5 trillion, making cybersecurity a top priority.

-

• Cyberattacks on smart warehouses are becoming more sophisticated.

-

• Over half of industrial manufacturers have experienced breaches.

-

• Companies invest in advanced security to protect data and operations.

Smart warehouses that embrace these warehouse trends will lead the industry in efficiency, flexibility, and security.

Warehouse robotics companies continue to transform supply chains. The table below shows how new technologies improve operations:

Technology Type — Description — Impact on Warehouse Operations Collaborative Robots — Work with humans — Boost efficiency and safety AMRs — Navigate in real time — Increase flexibility and speed AI and Machine Learning — Perform complex tasks — Adapt to changing needs

Businesses should analyze current activities, identify areas for improvement, and ensure new systems integrate smoothly. Regular maintenance and real-time monitoring help protect investments and workforce safety.

FAQ

What are the main benefits of warehouse robotics?

Warehouse robotics increase speed, accuracy, and safety. Companies see lower labor costs and fewer errors. Robots help workers focus on skilled tasks. Many businesses report higher customer satisfaction and faster order fulfillment.

How do companies measure the return on investment (ROI) for automation?

Companies track metrics like labor savings, error reduction, and order speed. Most see ROI within two to three years. Some use tables to compare costs before and after automation.

|

Metric |

Before Automation |

After Automation |

|---|---|---|

|

Labor Costs |

High |

Lower |

|

Error Rate |

Higher |

Lower |

Do robots replace human workers in warehouses?

Robots do not fully replace humans. They handle repetitive or heavy tasks. Workers move to roles that require problem-solving or technical skills. Upskilling programs help employees adapt to new technology.

What challenges do companies face when adopting warehouse robotics?

Companies face high upfront costs, training needs, and integration issues. Change management can be difficult. Some businesses also worry about cybersecurity and data protection.